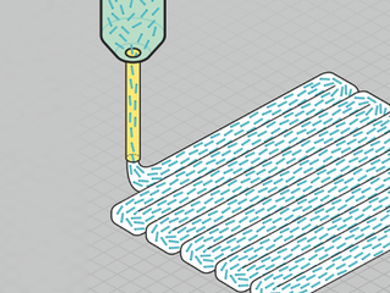

Direct ink writing (DIW) is a powerful printing method for the production of a broad range of materials with 3D features at the microscale. Since DIW is based on extrusion, the process requires inks with shear-induced thinning which readily form self-supporting structures once they have been deposited.

Tanja Zimmermann, Swiss Federal Laboratories for Materials Science and Technology, Dübendorf, Switzerland, Jennifer A. Lewis, Harvard University, Cambridge, MA, USA, André R. Studart, Swiss Federal Institute of Technology (ETH) Zurich, Switzerland, and colleagues have developed suitable viscoelastic inks by dispersing sustainable cellulose nanocrystals (CNCs) in either water or photopolymerizable monomer solutions. The water-based inks contained up to 20 wt% CNCs.

The printed structures have diameters of about 410 µm and show a shear-induced alignment of the rod-shaped CNC building blocks (pictured green). Inks containing both CNC and the monomers 2-hydroxyethyl methacrylate and polyether urethane acrylate formed CNC/polymer composites after UV curing. These materials showed enhanced mechanical properties, which were especially pronounced along the direction of the CNC alignment. The researchers point out the versatility of their approach for producing lightweight sustainable materials, in which the direction of reinforcement can be tailored to the desired application.

- Cellulose Nanocrystal Inks for 3D Printing of Textured Cellular Architectures,

Gilberto Siqueira, Dimitri Kokkinis, Rafael Libanori, Michael K. Hausmann, Amelia Sydney Gladman, Antonia Neels, Philippe Tingaut, Tanja Zimmermann, Jennifer A. Lewis, André R. Studart,

Adv. Funct. Mater. 2017.

DOI: 10.1002/adfm.201604619

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)