Wounds heal better when they are kept moist. Wound dressings can help with this, but also need to be gas-permeable, waterproof, and keep out bacteria. There has been research into biological materials with suitable properties, and silk fibroin has emerged as a possible candidate. Silk consists mainly of the proteins fibroin and sericin. Sericin is removed for medical applications because it could be attacked by the immune system. However, only a small number of silk fibroin-based medical products have so far been approved due to a lack of clinically relevant studies.

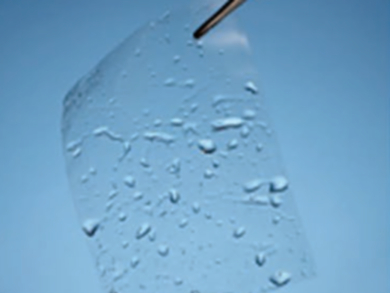

Hongwei Ouyang, Xiaohui Zou, Zhejiang University, Hangzhou, China, and colleagues have synthesized a silk fibroin film designed for wound dressing and have used both animal and clinical studies to provide systematic evidence for the material’s effectiveness. The team degummed raw silk and removed sericin in an Na2CO3 solution. The resulting silk fibroin was dissolved, cast into a mould, and subjected to temperature-controlled water vapor annealing (TCWVA) to improve crystallinity and prevent the finished transparent fibroin films (pictured) from being dissolved in water.

The researchers found that the resulting films were biocompatible. In studies on rabbits and pigs, the material improved the healing process when used as a wound dressing compared to uncovered wounds and compared to commercially available wound coverings. It also prevented infection and did not cause immunological complications. A controlled clinical study on human patients showed that the silk fibroin films were easier to handle and more effective than a commercially available wound dressing. According to the team, these results indicate that the clinical use of silk fibroin films for wound healing should be possible.

- Silk Fibroin Biomaterial Shows Safe and Effective Wound Healing in Animal Models and a Randomized Controlled Clinical Trial,

Wei Zhang, Longkun Chen, Jialin Chen, Lingshuang Wang, Xuexian Gui, Jisheng Ran, Guowei Xu, Hongshi Zhao, Mengfeng Zeng, Junfeng Ji, Li Qian, Jianda Zhou, Hongwei Ouyang, Xiaohui Zou,

Adv. Healthcare Mater. 2017.

DOI: 10.1002/adhm.201700121