Pliable and breathable electrodes are a key building block for wearable electronics. Since plain-woven fabrics are ideal candidates with respect to haptic and aesthetic perception, there is a need for methods that can add conductivity to these fabrics.

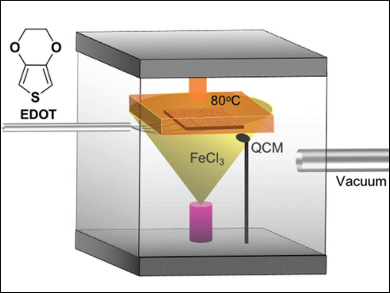

Trisha L. Andrew, University of Massachusetts Amherst, USA, and colleagues have used a vapor deposition method to transform fourteen off-the-shelf fabrics (including cotton, linen, silk, wool, bamboo, and bast) into fabric electrodes. First, samples were placed on a heated stage inside a vacuum chamber (pictured). A stream of 3,4-ethylenedioxythuiophene (EDOT) was then delivered to the position of the sample stage and polymerization was induced by an intersecting second vapor stream of a FeCl3 catalyst.

The resulting poly(3,4-ethylenedioxythiophene) (PEDOT) coating did not affect the feel or breathability of the fabrics. The materials showed good conductivity with a linear dependence on length, thereby making them useful for large-scale applications. The researchers point out the robustness of their materials against body heat, bending, laundering, and ironing – important requisites for the incorporation into garments.

- Rugged Textile Electrodes for Wearable Devices Obtained by Vapor Coating Off-the-Shelf, Plain-Woven Fabrics,

Lushuai Zhang, Marianne Fairbanks, Trisha L. Andrew,

Adv. Funct. Mater. 2017.

DOI: 10.1002/adfm.201700415