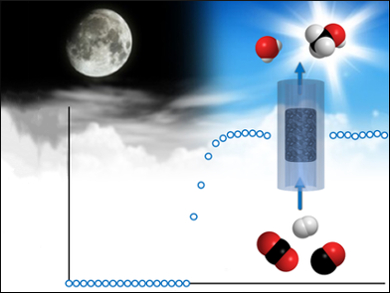

Solar energy can be used to reduce carbon dioxide and water to syngas (CO + H2) in a solar reactor. This can, in turn, be converted into liquid fuels and chemicals in a gas-to-liquid unit. The intermittent solar energy input can strongly affect the throughput and composition of the syngas. This can be a challenge for maintaining catalyst activity and stability.

By testing such a gas-to-liquid unit using daily startup–shutdown fluctuations, effectively mimicking the daily startup–shutdown cycles that would occur with sunlight, the mechanism of catalyst deactivation can be identified. This can be used to develop a robust chemical process under such variable conditions.

Javier Pérez-Ramírez, Aldo Steinfeld, Swiss Federal Institute of Technology (ETH) Zurich, and colleagues have studied the unsteady-state operation of a commercial Cu–ZnO–Al2O3 catalyst for the synthesis of methanol from syngas. Using realistic CO2-rich conditions, the catalyst was able to equilibrate quickly, and the activity responded well to fluctuations in the feed composition.

Upon initial testing, significant catalyst deactivation was observed after 27 daily startup–shutdown cycles, which also coincided with formation of ZnCO3 as an inactive species on the catalyst surface. However, by flushing with hydrogen-free syngas between cycles, this deactivation was largely inhibited, and the catalyst showed even better stability than in a steady-state experiment without cycling. These results may point the way to more stable catalytic processes and help enable the renewable synthesis of fuels and chemicals from carbon dioxide.

- Impact of Daily Startup-Shutdown Conditions on the Production of Solar Methanol over a Commercial Cu-ZnO-Al2O3 Catalyst,

Uri Ash-Kurlander, Oliver Martin, Luca D. Fontana, Vikas R. Patil, Men Bernegger, Cecilia Mondelli, Javier Pérez-Ramírez, Aldo Steinfeld,

Energy Technol. 2016, 4, 565–572.

DOI: 10.1002/ente.201600022