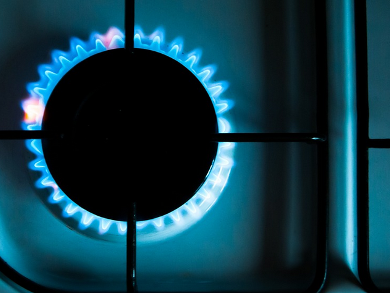

Linde and Evonik have concluded an exclusive cooperation agreement on the use of membranes for natural gas processing. They will jointly promote membrane technology – Evonik on the membrane and polymer side and Linde’s Engineering Division as the system integrator for the complete membrane package units. The joint product will be marketed by Linde as the “HISELECT™ powered by Evonik” high-performance membrane package unit.

Evonik has developed its polymer-based membrane technology further for the area of natural gas and has recently commercialized it: SEPURAN® NG is an especially robust, hollow-fiber membrane, based on a high-performance plastic that can withstand extreme pressure and temperatures. This enables selective separation of the sour gases from the natural gas, high tolerance of the higher hydrocarbons contained in the natural gas, and consistently high performance of the membrane throughout its lifetime. According to the company, their technology significantly increases recovery of methane, which has a corresponding effect on the profitability of natural gas processing plants.

Evonik’s SEPURAN® product family includes membranes for biogas upgrading, nitrogen generation, and helium and hydrogen processing. They are produced at the Evonik site in Schörfling, Austria. The basic material – the high-performance plastic – is manufactured in their neighboring site in Lenzing.

- Evonik Industries AG, Essen, Germany

- The Linde Group, Munich, Germany