3D manufacturing techniques at the micro- and nanoscale are, for example, used to create micro- and nano-electromechanical systems. Components based on ceramic materials would massively increase the range of possible uses of such systems. However, the production of ceramic materials at such a small scale is challenging. There is a lack of suitable precursors, and the high shrinkage during the ceramization process at high temperatures can result in poor definition or incompletely ceramized products.

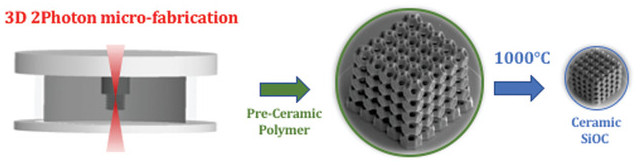

Giovanna Brusatin, University of Padova, Italy, and colleagues have used a solvent-free acrylate siloxane precursor along with bis(dimethylamino)benzophenon (BDEBP) for the 3D nanofabrication of SiOC ceramic structures. The team used direct laser writing with a pulsed laser, which has a beam that is tightly focused into a small volume (pictured below). During the laser writing, a rapid two-photon polymerization of BDEPB occurs, resulting in a crosslinking of the siloxane pre-ceramic polymers. The researchers used an unconventional printing configuration by inverting the writing direction from “up” to “down”, adding layer by layer in direction of the negative z-axis.

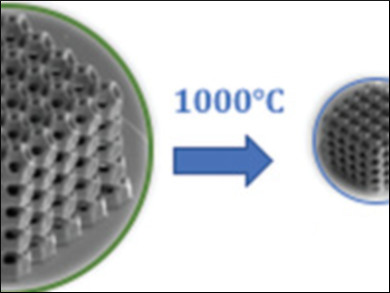

The ceramic structures, obtained after pyrolysis at 1000 °C, are dense and crack-free despite the mass loss during ceramization. Using this technique, the team was able to build ceramic structures with a height of up to 0.1 mm and details down to 450 nm with fully ceramized SiOC.

- 3D Nanofabrication of SiOC Ceramic Structures,

Laura Brigo, Johanna Eva Maria Schmidt, Alessandro Gandin, Niccolò Michieli, Paolo Colombo, Giovanna Brusatin,

Adv. Sci. 2018.

https://doi.org/10.1002/advs.201800937