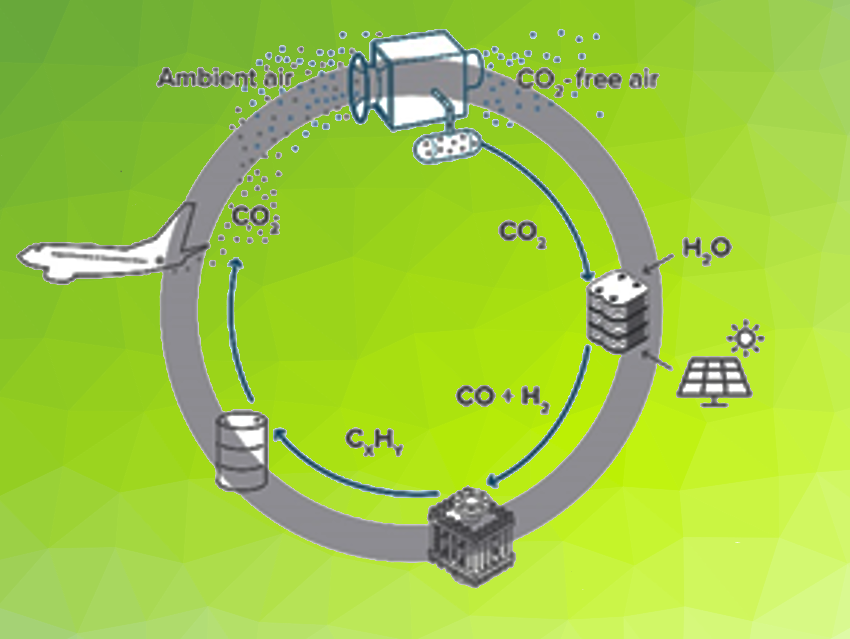

The Rotterdam The Hague Airport, The Netherlands, cooperates with European companies to develop a demonstration plant that produces renewable jet fuel from air-captured CO2 and electricity. Compared to conventional fossil-based jet fuels, it has a lower carbon footprint and fine particles emission. The demonstration plant will produce about 1000 liters of renewable jet fuel per day. This would be the first time that renewable jet fuel from air production exceeds laboratory scale of a few liters per day, the companies say.

First, CO2 is captured from ambient air by Climeworks’ direct air capture technology. The gas is subsequently transformed into syngas (H2, CO, CO2) through electrolysis, using electrolyser cells (solid oxide electrolyser cells, SOECs) developed by Sunfire. The syngas is turned into synthetic hydrocarbons by means of Fischer-Tropsch synthesis, enabled by Ineratec. The synthetic hydrocarbons are converted into jet fuel by EDL. This company is also responsible for the overall process and plant integration. When renewable energy is used, the entire process runs sustainably. Preferably the energy is produced on site from the airport’s solar panels.

The study will define the concept and basic engineering for onsite production of renewable jet fuel from air and will allow a cost estimate for both the actual construction of the plant and the fuel itself. The large-scale production of renewable jet fuel requires an upscaling and, where beneficial, integration into existing refineries. This will not take place at the airport.

- EDL Anlagenbau GmbH, Leipzig, German

- Climeworks AG, Zurich, Switzerland

- Sunfire GmbH, Dresden, Germany

- Ineratec GmbH, Karlsruhe, Germany

- Rotterdam The Hague Airport, Rotterdam, The Netherlands