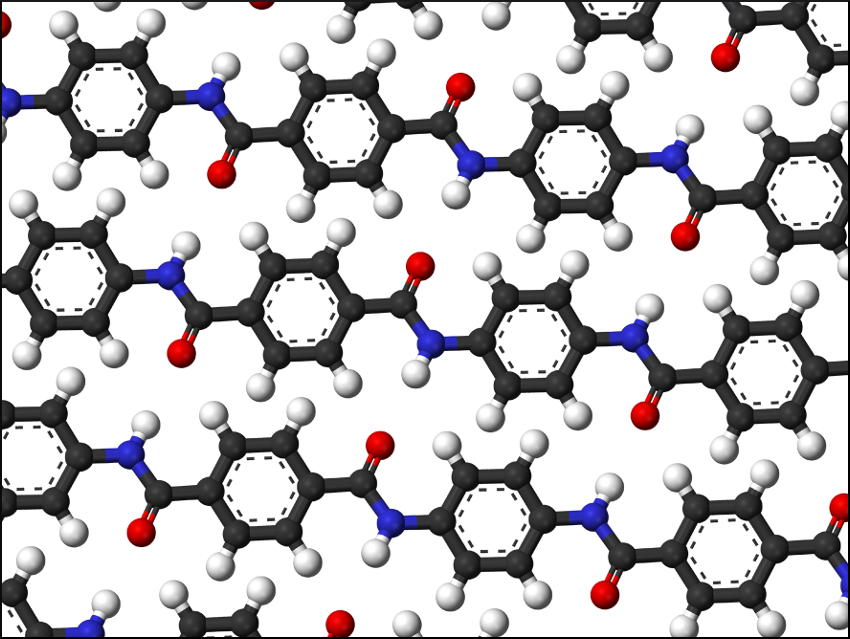

Aramid fibers such as Kevlar (structure pictured) are used in body armor, aerospace technology, and even in bicycle tires. Aramid nanofibers (ANFs), in particular, have high mechanical strength, are electrically insulating, flame-retardant, and chemically resistant. However, most of the methods for producing these nanofibers take a long time. There are also difficulties in judging the endpoint of the reaction.

Bin Yang and colleagues, Shaanxi University of Science and Technology, Xi’an, China, have developed a quick and efficient method for fabricating ANFs. Poly (p-phenylene terephthalamide) (PPTA) fibers, i.e., aramid, were turned into nanofibers using either a milling-assisted method (fibrillation), an ultrasonication-assisted method, or a proton-donor-assisted method with added water. In each case, the fibers were formed in a dimethyl sulfoxide (DMSO) solution and then turned into a film using vacuum-assisted filtration.

The endpoint of the deprotonation reaction which forms the nanofibers was detected using Raman spectroscopy and the cationic demand of the ANF/DMSO system. The cationic demand of a sample equals the amount of highly charged cationic polymer required to neutralize its surface.

Of the three fabrication methods, the proton-donor-assisted deprotonation method was found to be the most efficient. This method shortens the fabrication time from the usual seven days to four hours. The fabricated ANFs have a high rigidity, a small diameter, and a narrow size distribution of 10.7 ± 1.0 nm.

- Timesaving, High-Efficiency Approaches To Fabricate Aramid Nanofibers,

Bin Yang, Lin Wang, Meiyun Zhang, Jingjing Luo, Xueyao Ding,

ACS Nano 2019.

https://doi.org/10.1021/acsnano.9b02258