The catalytic reduction of CO2 could allow its use as a renewable feedstock for the chemical industry. However, the mechanism of this reaction is not well understood. Cobalt aminopyridyl complexes, together with photosensitizers, are possible catalysts for this reaction. Their structure and properties are tunable, which makes them good model systems to investigate CO2 reduction. While these catalyst systems show high activity in light-driven CO2 reduction, their electrocatalytic activity is limited.

Josep María Luis, University of Girona, Spain, Julio Lloret-Fillol, Institute of Chemical Research of Catalonia (ICIQ), Tarragona, and Catalan Institution for Research and Advanced Studies (ICREA), Barcelona, both Spain, and colleagues have investigated the mechanism of a photo- and electrocatalytic cobalt-aminopyridyl-catalyzed CO2 reduction and identified bottlenecks that hamper the performance of the catalyst system. The team used a cobalt(II) triflate complex with a 1-(2-pyridylmethyl)-4,7-dimethyl-1,4,7-triazacyclononane ligand, together with iridium-based photosensitizers. They performed electrochemical studies and UV-Vis, infrared (IR), extended X-ray absorption fine structure (EXAFS), and NMR spectroscopy, as well as density functional theory (DFT) calculations.

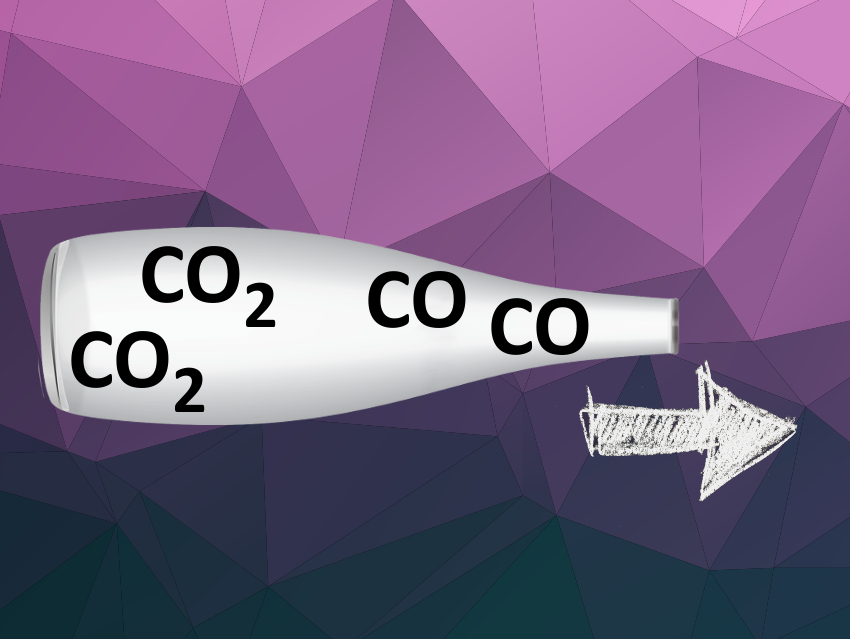

The researchers found that the catalyst is converted to a Co(I)-CO complex in the electrocatalytic cycle. The release of CO from this catalyst requires energy and is a limiting step. The team used an additional photocatalytic strategy to avoid this: Light-induced metal carbonyl dissociation can improve the catalytic performance. This might make irradiation with blue light a promising strategy to prevent CO catalyst poisoning. This work could also help scientists to understand the behavior of other cobalt-based electrocatalysts.

- A Unified Electro- and Photocatalytic CO2 to CO Reduction Mechanism with Aminopyridine Cobalt Complexes,

Sergio Fernández, Federico Franco, Carla Casadevall, Vlad Martin-Diaconescu, Josep María Luis, Julio Lloret-Fillol,

J. Am. Chem. Soc. 2019.

https://doi.org/10.1021/jacs.9b06633