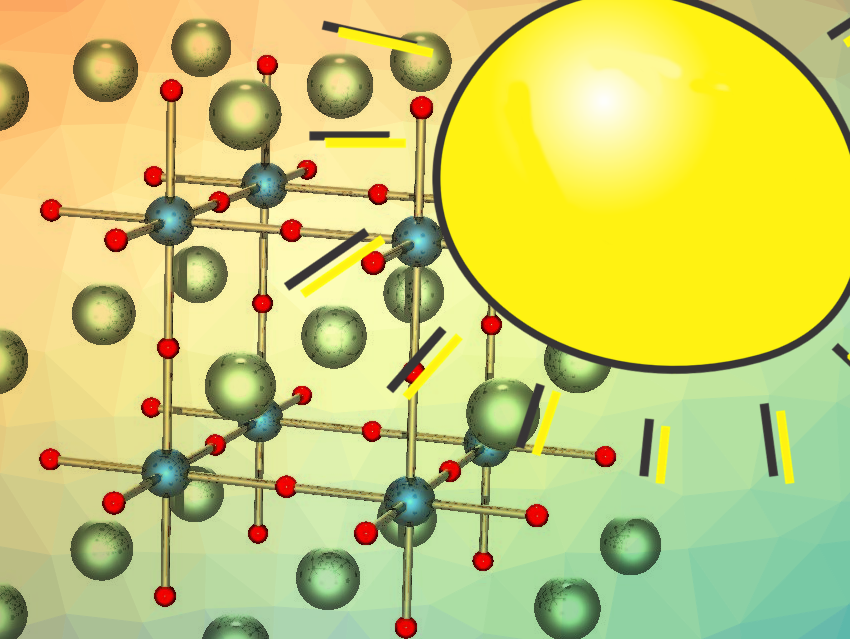

Ruddlesden-Popper perovskite (RPP) films can be used as light absorbers in perovskite solar cells. They consist of a small organic cation (formamidinium or methylammonium) and inorganic layers of lead or tin halide octahedra. Moreover, a large bulky organic cation forms a bilayer sandwiched between the octahedra layers. The number of inorganic layers between an organic bilayer is described with n, ranging from 1 to infinity. The resulting phases are two-dimensional (2D) and three-dimensional (3D) perovskites, respectively. A pure 2D perovskite has the widest band gap and poor charge transport properties compared to 3D perovskites. Depending on the protocol and solvent used for spin-coating, the type of phases and the film quality vary a lot.

Shuyan Shao, Maria Antonietta Loi, University of Groningen, The Netherlands, and colleagues have developed a fabrication method for a phenylethylammonium methylammonium lead iodide RPP with the solvent dimethyl sulfoxide (DMSO). Usually, RPP films made conventionally by spin-coating a DMSO precursor solution are segregated and rough. The researchers evaporated the DMSO in vacuum directly after spin-coating and obtained much more uniform-looking films.

The team found a more favorable phase segregation in these films compared to the samples made without vacuum assistance. The films show mostly the favorable 3D structure, and the 2D phases are significantly smaller. Moreover, the inorganic slabs of the 3D perovskites were oriented not parallel, but perpendicular towards the substrate. This is more favorable for the device performance, as the charge transport is not blocked in the vertical direction. The low-n-phases with parallel orientation were very small and only at the bottom at the film. A device built with these films showed a good performance with efficiency up to 14.14 %.

- Tuning the Energetic Landscape of Ruddlesden–Popper Perovskite Films for Efficient Solar Cells,

Shuyan Shao, Herman Duim, Qingqian Wang, Bowei Xu, Jingjin Dong, Sampson Adjokatse, Graeme R. Blake, Loredana Protesescu, Giuseppe Portale, Jianhui Hou, Michele Saba, Maria Antonietta Loi,

ACS Energy Letters 2019.

https://doi.org/10.1021/acsenergylett.9b02397