Multilayer packaging, in which different materials are combined in a layered structure, represents the most common type of nonrecyclable packaging. These types of packaging are used particularly often because a combination of materials allows for tailor-made properties. However, in many cases the different polymers or materials used are immiscible, and the packages can, thus, not be recycled. In current recycling systems, multilayer packaging is generally picked out and sent to incineration.

Katharina M. A. Kaiser, Technical University of Munich and Fraunhofer Institute for Process Engineering and Packaging IVV, both Freising, Germany, has developed an approach for the production of recyclable multilayer packing that uses laminating adhesives with reversible cross‐links. These adhesives can be removed after use, leaving separate recyclable materials.

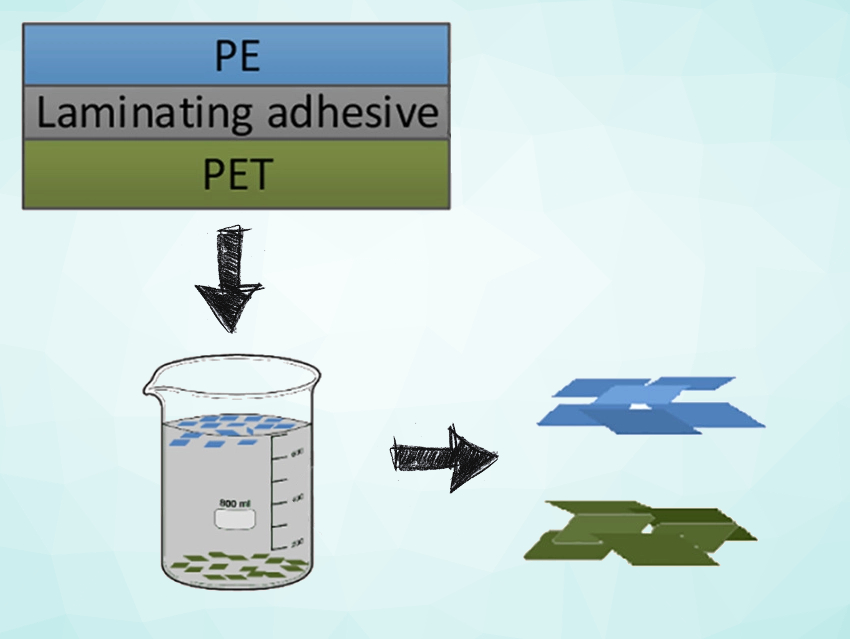

Kaiser used linear polyester–PU prepolymers functionalized with maleimide/furan groups as the adhesive, together with a cross‐linking molecule containing three furan groups. Using this adhesive in the form of an ethyl acetate solution, she prepared PET/PE, PET/aluminum, and PE/aluminum laminates (PET = polyethylene terephtalate, PE= = polyethylene) using a hand‐held roller. The laminate samples were then cured both at room temperature and 60 °C under pressure from a weight. During this process, a Diels–Alder reaction between furan- and maleimide derivatives causes the desired cross-linking.

After use, the resulting multilayer materials can be delaminated at 105 °C in dimethylsulfoxide (DMSO) under moderate shearing. Under these conditions, a retro-Diels–Alder reaction is induced and the adhesive dissolves. The monomaterial films are left in the resulting suspension (example pictured) and can be easily separated, dried, and finally recycled. The solvent can also be recovered and, due to the low concentration of the adhesive’s monomers, it can be used again directly for at least ten rounds of delamination.

- Recycling of multilayer packaging using a reversible cross-linking adhesive,

Katharina M. A. Kaiser,

J. Appl. Polym. Sci. 2020.

https://doi.org/10.1002/app.49230