Crude oil needs to be separated into its components before use. This separation is performed on a large scale using thermal distillation, which consumes large amounts of energy. Energy-efficient membrane-based separations could be a greener alternative—or a complement—to conventional distillation approaches. However, there is a lack of suitable membrane materials for this application.

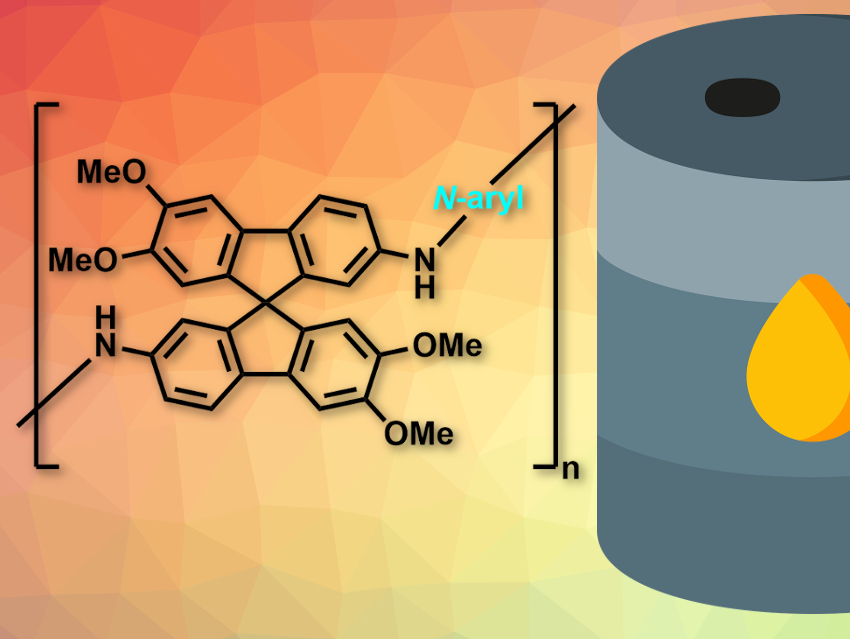

Ryan P. Lively, M. G. Finn, Georgia Institute of Technology, Atlanta, USA, and colleagues have developed spirocyclic polymers with N-aryl linkers (pictured), which can be used to create microporous membranes for the fractionation of light crude oil. The team used a dibrominated spirobifluorene building block, which was polymerized with different diaminoaryls using a palladium-catalyzed Buchwald–Hartwig amination. The resulting spirobifluorene aryl diamine (SBAD) polymers were cast to create microporous films.

The team compared the separation performance of SBAD with the prototypical microporous polymer PIM-1. Using a mixture of of 1,3,5-triisopropylbenzene (TIPB) and toluene as a model system, they found that all SBAD polymer membranes held back the TIPB more efficiently than PIM-1, with the highest-performing polymer rejecting 80 % of the TIPB. The separation properties of SBAD membranes depend both on the size and the aromaticity of the hydrocarbons.

The researchers also tested the SBAD membranes in the separation of light crude oil. Passing the crude oil through the membrane significantly enriched the lighter molecules and held back heavier hydrocarbons. According to the researchers, the combination of energy-efficient membrane technology with conventional processes such as distillation could help to save energy and carbon emissions.

- N-Aryl–linked spirocyclic polymers for membrane separations of complex hydrocarbon mixtures,

Kirstie A. Thompson, Ronita Mathias, Daeok Kim, Jihoon Kim, Neel Rangnekar, J. R. Johnson, Scott J. Hoy, Irene Bechis, Andrew Tarzia, Kim E. Jelfs, Benjamin A. McCool, Andrew G. Livingston, Ryan P. Lively, M. G. Finn,

Science 2020.

https://doi.org/10.1126/science.aba9806