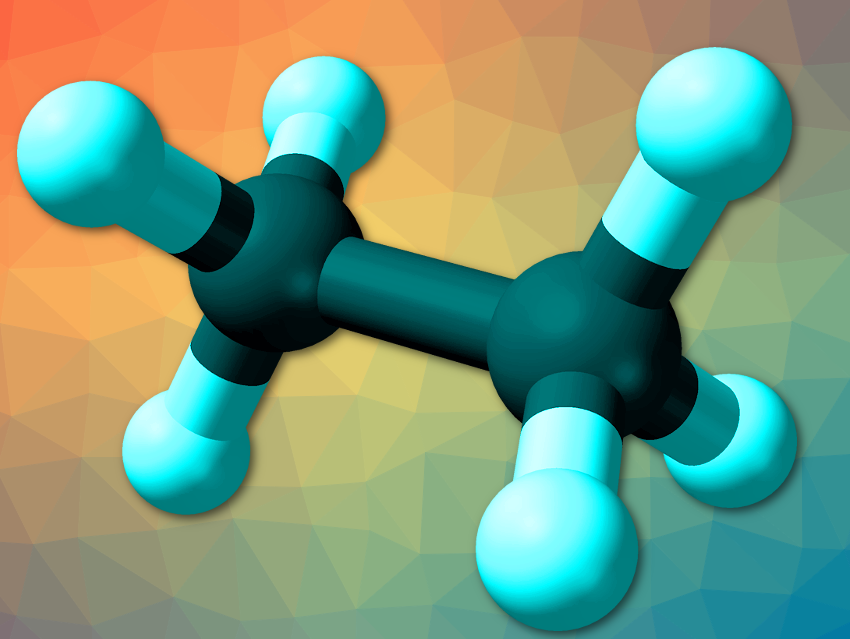

Clariant Catalyts and Linde Engineering have combined their know-how and developed catalysts for the oxidative dehydrogenation of ethane (ODH-E) and an innovative ethylene production technology (EDHOX™). The catalysts make this type of ethylene production commercially feasible. They offer high selectivity for ethylene and acetic acid (up to 93 %) in the oxidative dehydrogenation of ethane and show excellent productivity while the formation of by-products is minimized.

The EDHOX™ technology has been successfully validated for commercial use in a full-scale demonstration plant. The process is suitable for the production of ethylene as well as ethylene and acetic acid to produce chemicals such as vinyl acetate monomer, ethylene-vinyl acetate copolymer or polyvinyl alcohol products.

Unlike conventional steam cracking, which operates at process temperatures of up to 900 °C, the EDHOX™ technology is operated at moderate temperatures of below 400 °C. This results in comparatively low CO2 emissions. In addition, the CO2 can be sequestered, or the power generation can be electrified. Together, this leads to a reduction of CO2 emissions of up to 100 % compared with conventional ethane steam cracking, according to the companies.

- Clariant AG, Muttenz, Switzerland

- Linde plc, Dublin, Ireland