Hybrid catalysts that combine semiconductors and cocatalysts can be used for the photoelectrochemical conversion of CO2 to value-added chemicals, e.g., formic acid (HCOOH). A cocatalyst is generally required to overcome the sluggish kinetics of silicon photoelectrodes and improve the overall catalytic activity. Noble metals or copper can be used for this purpose, but noble metals are expensive and copper catalysts have issues when it comes to the selectivity of the reaction. In addition, impurities in CO2-containing flue gas have to be kept in mind when developing suitable catalysts. H2S impurities, for example, can poison the catalyst.

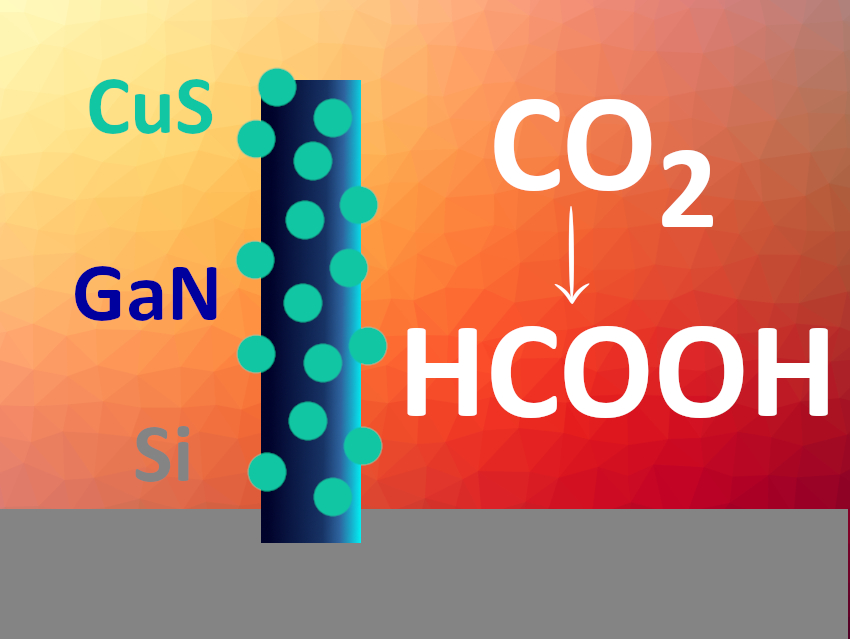

Jong-Lam Lee, Pohang University of Science and Technology (POSTECH), Republic of Korea, Zetian Mi, University of Michigan, Ann Arbor, USA, and colleagues have developed a photocathode consisting of CuS-nanoparticle-coated GaN nanowires on a silicon photocathode (pictured schematically), which can be used for reducing H2S-containing CO2 gas to HCOOH. The team used plasma-assisted molecular beam epitaxy for growing GaN nanowires on a silicon wafer. Then, Cu nanoparticles were deposited on the nanowires via thermal evaporation. Finally, H2S impurities in a simulated industrial CO2 gas allowed the spontaneous transformation of the copper nanoparticles to CuS nanoparticles.

The resulting hybrid catalyst provides efficient light harvesting, effective charge carrier transport, and a large number of catalytically active sites. With this approach, sulfur compounds in the flue gas can enhance the activity via the formation of CuS instead of poisoning the catalyst. A corresponding catalyst with Cu nanoparticles instead of CuS performed worse in the photoelectrochemical CO2 reduction. The CuS/GaN/Si photocathode showed a high faradaic efficiency for the production of HCOOH of 70.2 %.

- CuS-Decorated GaN Nanowires on Silicon Photocathodes for Converting CO2 Mixture Gas to HCOOH,

Wan Jae Dong, Ishtiaque Ahmed Navid, Yixin Xiao, Jin Wook Lim, Jong-Lam Lee, Zetian Mi,

J. Am. Chem. Soc. 2021.

https://doi.org/10.1021/jacs.1c02139