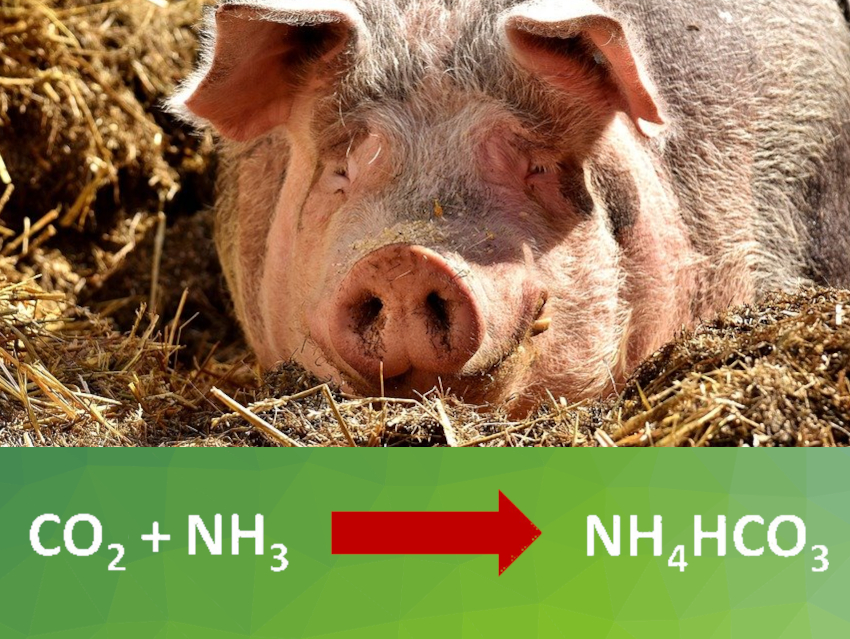

Animal metabolism produces waste gases such as CO2 and ammonia, which is released from animal waste. These gases are an important part of the environmental footprint of agriculture. At the same time, agriculture depends on fertilizers containing nitrogen compounds, which are usually produced using the energy-intensive Haber–Bosch process. Capturing and utilizing ammonia from animal waste gases could, therefore, improve agricultural sustainability. However, this is challenging due to the comparatively low ammonia concentrations in the air in, e.g., stables and pigsties.

Akira Takahashi, Tohru Kawamoto, National Institute of Advanced Industrial Science and Technology (AIST), Tsukuba, Japan, and colleagues have developed a method to adsorb ammonia and CO2 from gaseous animal waste and harvest solid ammonium bicarbonate (NH4HCO3), which can be used as fertilizer. The team used materials based on Prussian blue that have a high adsorption capacity due to a porous crystal structure. A Cu-substituted Prussian-blue analogue (CuPBA) with an increased number of adsorption sites for ammonia was chosen and tested under laboratory conditions.

Commercially available CuPBA beads with a polyvinyl alcohol binder were loaded onto a column and CO2 and NH3 were passed through to test the adsorption capacity. Ammonium bicarbonate was isolated by sublimation, and no significant amounts of toxic cyanide ions were detected. The adsorption capacity was not adversely affected by the presence of water, which would be present when the system is used in actual stables.

The system was then tested under real-life conditions in a piggery. The team installed a gas-trapping system containing the CuPBA beads in the ceiling and operated it for one week. Solid ammonium bicarbonate was successfully isolated. Thus, the researchers were able to show that waste gases from animal stables can be successfully converted to solid fertilizers using a commercially available material. If the process can be made economically feasible, it could help to reduce agricultural emissions.

- Harvesting a Solid Fertilizer Directly from Fetid Air,

Akira Takahashi, Kimitaka Minami, Keiko Noda, Koji Sakurai, Tohru Kawamoto,

ACS Sustainable Chem. Eng. 2021.

https://doi.org/10.1021/acssuschemeng.1c06161