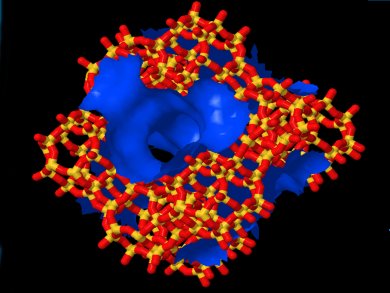

For decades, the oil industry has been trying to improve the accessibility of zeolites to boost activity and improve selectivity in the petrochemical refining process. Javier García-Martínez, Director of the Molecular Nanotechnology Lab, University of Alicante, Spain, and colleagues describe a new surfactant-based, simple, and inexpensive technique that allows precisely controlled mesoporosity to be introduced within a wide range of zeolite crystals, while maintaining the chemical and physical properties of the zeolites, i.e., microporosity, crystallinity, acidity. Pore size is tuned using surfactants of different lengths. The pore volume is adjusted with the severity of the treatment.

Mesostructured zeolite Y was formed into a fluid catalytic cracking (FCC) catalyst in a pilot plant at River Technology, a company formed to commercialize the technology, and extensively tested in an ACE unit (automated fluidized bed test) for catalytic cracking of vacuum gas oil. The materials show significantly improved selectivity, resulting in shifting product yields, increased transportation fuels (e.g, gasoline and light cycle oil) and less coke, dry gases, and uncracked bottoms.

It is the first time that well-controlled mesoporosity is introduced into Y zeolites with low Si/Al ratios, which are relevant to catalytic cracking. The mesostructured zeolite Y also demonstrated excellent hydrothermal stability critical to such applications.

Mesostructured zeolites are not only superior FCC catalysts, but also ideal materials for a wide variety of other applications whereby slow diffusion presents a limiting factor in the reaction process, such as in hydrocracking. Other potential applications include catalytic pyrolysis of biomass, catalytic upgrading of bio-oil, transesterification of vegetable oil, methanol conversion to hydrocarbons, water treatment, and less energy-intensive adsorptive separations.

Image: © J. García-Martínez

- Mesostructured zeolite Y—high hydrothermal stability and superior FCC catalytic performance,

Javier García-Martínez, Marvin Johnson, Julia Valla, Kunhao Li, Jackie Y. Ying,

Catal. Sci. Technol. 2012.

DOI: 10.1039/c2cy00309k