Inkjet printing of graphene is a promising research direction, as it combines the attractive features of inkjet printing with the unique electronic, optical and mechanic properties of graphene. Inkjet printing fabricates functional devices or films through well-controlled ejection of droplets of liquid phase materials (inks) from nozzles onto various substrates. There has been no sophisticated inkjet printing technology to date to allow efficient and reliable mass production of high-quality graphene films/patterns for practical applications.

Jiantong Li and colleagues, KTH Royal Institute of Technology, Kista, Sweden, and Max C. Lemme, University of Siegen, Germany, have developed an efficient and mature inkjet printing technology for mass production of coffee-ring-free patterns of high-quality graphene at high resolution.

To prepare high-concentration graphene dispersions, graphene is first exfoliated from graphite flakes in DMF. Before distillation, a small amount of polymer (ethyl cellulose) is added into the harvested graphene/DMF dispersion to protect the graphene flakes from agglomeration. Then DMF is exchanged by terpineol through distillation by virtue of the large difference between their boiling points. The solvent is changed from low-viscosity and toxic DMF to high-viscosity and environmentally-friendly terpineol.

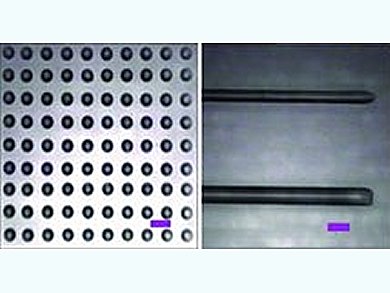

This combination of solvent exchange and polymer stabilization techniques results in stable graphene inks with high concentration and compatible fluidic characteristics for efficient and reliable inkjet printing. The mixture of high- and low-contact-angle solvents together with polymers in the inks suppresses the coffee-ring effect through unpinning of the contact lines during solvent evaporation. After printing, the stabilizing polymers can be effectively removed through a simple annealing process.

The technology facilitates the fabrication of a variety of graphene devices and is a promising alternative for future commercial applications in printed and flexible electronics.

- Efficient Inkjet Printing of Graphene,

Jiantong Li, Fei Ye, Sam Vaziri, Mamoun Muhammed, Max C. Lemme, Mikael Östling,

Adv. Mater. 2013.

DOI: 10.1002/adma.201300361