Printed electronics are cheap to manufacture and useful for a variety of applications such as electronic labels, flexible displays, and wearable electronics. Screen-printing, which is usually used to print, e.g., designs on t-shirts, is a particularly cost-effective and easy printing method.

Qibing Pei and colleagues, University of California, Los Angeles, USA, have developed a water-based ink for screen-printing electronics that contains silver nanowires (AgNWs). The team used distilled water as the solvent and silver nanowires with an average diameter of 25–35 nm and an average length of 15–25 µm as the conductive components of the ink. They added a mixture of (hydroxypropyl)methyl cellulose as a binder, a fluorinated surfactant, and an antifoaming agent to prepare the final ink.

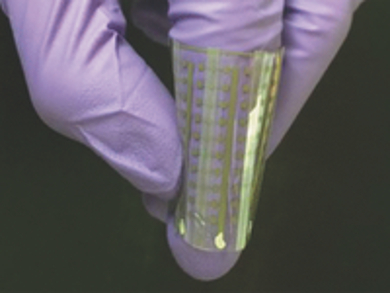

The researchers screen-printed the ink on both flexible PET and rigid glass substrates and annealed the printed structures at 150 °C. They were able to generate sharp-edged lines with resolutions of 50 µm. As a proof-of-concept, the team fabricated a wearable flexible thin-film transistor (TFT) array (pictured), which exhibit uniform channels and good stability. According to the team, the approach is promising for the production of stretchable and wearable electronics.

- A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors,

Jiajie Liang, Kwing Tong, Qibing Pei,

Adv. Mater. 2016.

DOI: 10.1002/adma.201600772