Plastic waste is a growing environmental problem. Ths use of more sustainable materials could help with this issue and also reduce the dependency on fossil resources. Polylactic acid (PLA) is a derivative of lactic acid, which can be produced from renewable resources such as wheat, straw, or corn. It is a promising environmentally friendly polymer and can be decomposed by microbes. PLA can be produced via a ring-opening polymerization (ROP) of lactide, the cyclic diester of lactic acid, promoted by metal complexes. Zinc complexes could be useful as catalysts for this type of reaction due to their low cost and low toxicity.

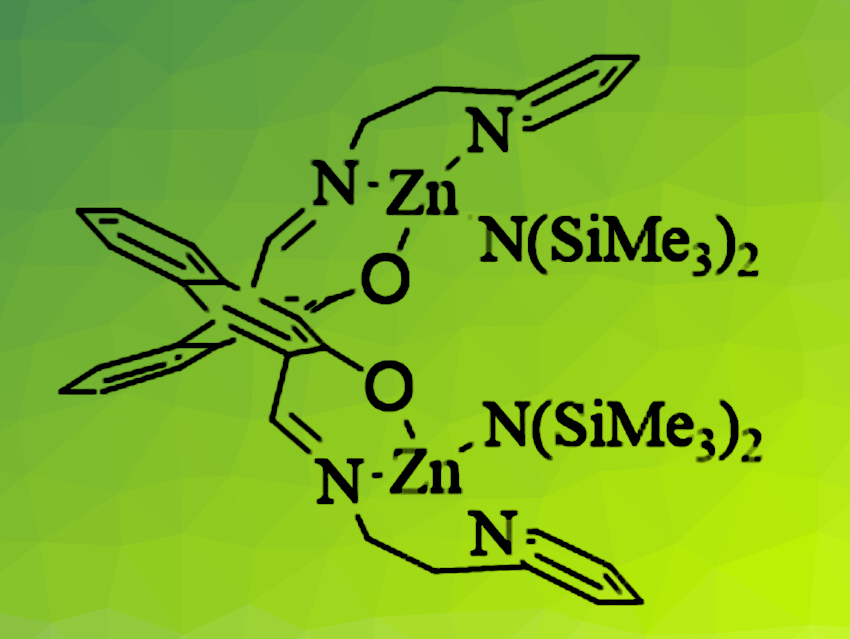

Marina Lamberti, Mina Mazzeo, University of Salerno, Italy, and colleagues have synthesized dinuclear zinc complexes (pictured) with hexadentate ligands that contain imine and pyridine groups and a binaphthol backbone. These complexes can serve as catalysts for the polymerization of lactide. The bis(iminopyridine)binaphthol ligand was obtained via the condensation of two equivalents of 2-(2-pyridyl)ethylamine with 3,3′-diformyl BINOL. The ligand was then reacted with two equivalents of zinc bis[bis(trimethylsilyl)amide] in benzene to obtain the desired dizinc complex. The team found that at room temperature, the complex exists mainly as a dimeric species in solution.

The catalyst, in combination with an alcohol as a cocatalyst, produced polylactide via the ring-opening polymerization of lactide. The team found that the catalyst system provides high activities and a good control of the process, leading to polymers with desired molecular weights, even when working under harsh industrial conditions and employing technical-grade melted lactide. Interestingly, modifying the reaction conditions allows the process to switch towards the exclusive formation of macrocyclic PLA via back-biting reactions that compete with the propagation reaction.

- Zinc Complexes Bearing Dinucleating Bis(iminopyridine)binaphthol Ligands: Highly Active and Robust Catalysts for the Lactide Polymerization,

Federica Santulli, Filippo Bruno, Mina Mazzeo, Marina Lamberti,

ChemCatChem 2023.

https://doi.org/10.1002/cctc.202300498