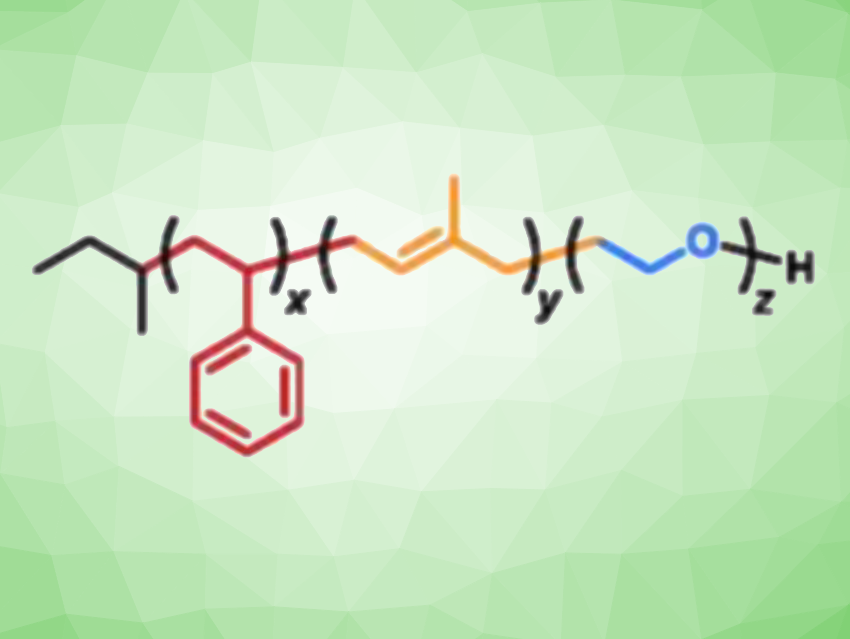

Polyolefin-b-poly(ethylene oxide) (PEO) is a widely investigated type of amphiphilic block copolymer. Anionic polymerization allows the one-pot sequential block copolymerization of vinyl monomers and ethylene oxide (EO) while avoiding side reactions and the introduction of additional end-group components. However, it has remained challenging to achieve high block efficiency, high polymerization efficiency, and high molar mass for PEO.

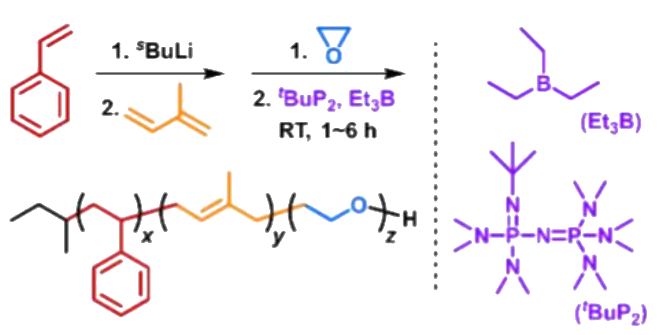

Junpeng Zhao, Guangzhao Zhang, South China University of Technology, China, and colleagues have developed a one-pot hybrid block copolymerization approach in which polyolefins (isoprene/styrene, pictured in yellow and red below) are first formed by sBuLi-initiated anionic vinyl-addition polymerization. They are then used in-situ as macroinitiators for the anionic ring-opening polymerization (ROP) of EO, aided by a two-component organocatalyst which separates O–Li ion pairs and breaks up chain-end aggregation (pictured below in purple).

The cooperative effect of the organobase and triethylborane turned out to be effective, allowing the team to achieve high ROP efficiency, narrow molar mass distribution, and controlled block lengths and composition at room temperature. They demonstrated the versatility of the approach by the one-pot synthesis of tri-/tetrablock ter-/quaterpolymers consisting of polyisoprene (PI), polystyrene (PS), PEO, and poly(propylene oxide). Interestingly, one polystyrene-b-polyisoprene-b-PEO triblock terpolymer with a specific composition was found to form in vesicle-type aggregates when dispersed in water.

- Hybrid anionic block copolymerization: From organocatalysis‐streamlined crossover to internally microphase‐separated aggregates,

Lijun Liu, Heng Li, Pengfei Zhang, Yubo Zhou, Junpeng Zhao, Guangzhao Zhang,

Aggregate 2024.

https://doi.org/10.1002/agt2.541