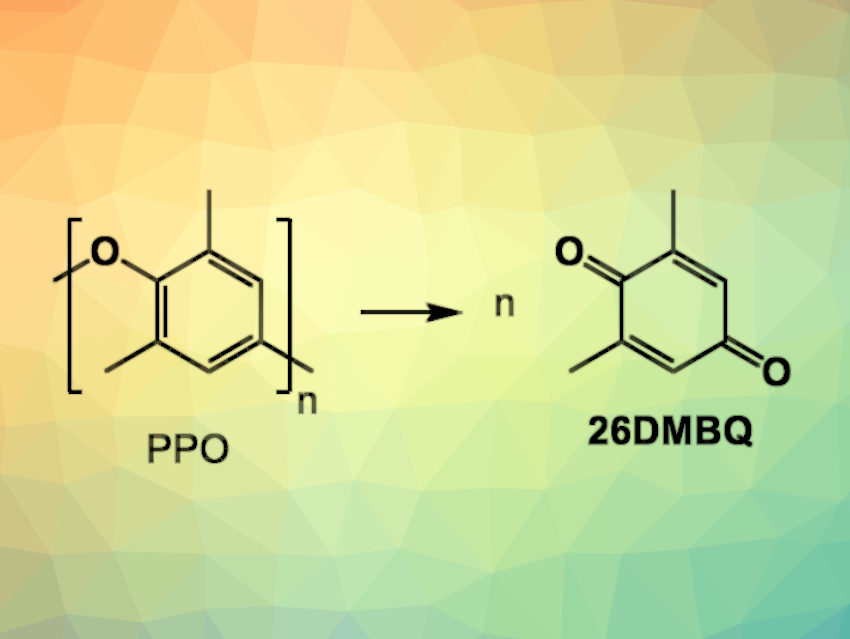

Poly(2,6-dimethyl-1,4-phenylene oxide) (PPO) is an important type of engineering plastic. It is often blended with other plastics such as high-impact polystyrene (HIPS) for use in, e.g., automotive components. Existing methods for the chemical recycling of PPO are limited, and new approaches to converting PPO waste into single aromatic compounds would be useful.

Yumiko Nakajima, National Institute of Advanced Industrial Science and Technology (AIST), Tsukuba, Japan, and Tokyo Institute of Technology, Japan, and colleagues have developed a method for the chemical recycling of PPO via oxidative depolymerization to form 2,6-dimethyl-p-benzoquinone (26DMBQ) as a sole aromatic product. The team used nitronium ions (NO2+) as a mild oxidant, and the desired product was obtained in 66 % yield. NO2+ was generated from a combination of silicotungstic acid and nitrate salts at a moderate temperature of 120 °C.

Mechanistic studies showed that PPO was oxidized by NO2+ and then attacked by H2O to achieve C–O bond cleavage, resulting in the formation of 26DMBQ. 26DMBQ was further used in a polymerization with a dianiline to form a polyimide. Overall, the work provides a new chemical recycling process for PPO that enables the recovery of aromatic compounds under mild conditions.

- Oxidative Depolymerization of Polyphenylene Oxide into Benzoquinone,

Yoshihiro Shimoyama, Yumiko Nakajima,

ChemSusChem 2023.

https://doi.org/10.1002/cssc.202300684

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)