Dispersions of polymer particles in a liquid phase (latexes) have many important applications in coatings technology, medical imaging, and cell biology. Elodie Bourgeat-Lami, Emmanuel Lacôte, Muriel Lansalot, Université Claude Bernard Lyon 1, Villeurbanne, France, and colleagues have developed a method for the production of stable polystyrene dispersions with unprecedentedly large and uniform particle sizes. Narrow size distributions are essential in many advanced technologies, but were previously difficult to produce photochemically.

Polystyrene Particles in Dispersions

Polystyrene, often used to create expanded foam, is also well suited to the production of latexes, in which microscopically tiny polystyrene particles are suspended in a dispersion. They are used in the manufacture of coatings and paints, but also for calibration purposes in microscopy as well as in medical imaging and cell biology research. They are usually produced by a thermally induced or redox-induced polymerization within the solution.

Controlled Photopolymerization

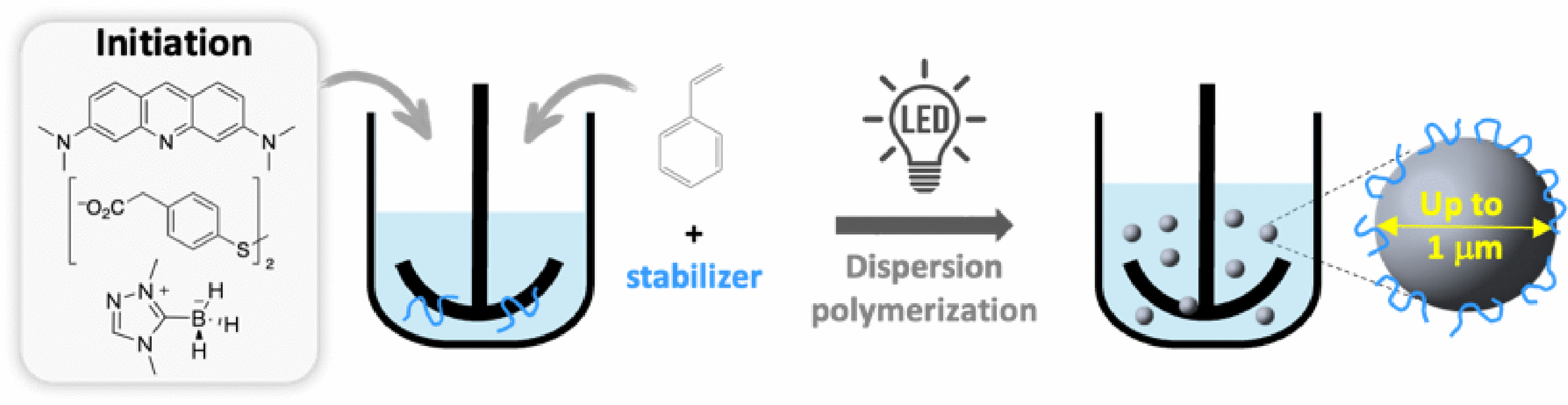

To gain external control over the process, the team turned to light-driven processes. Light-driven polymerization ensures temporal control, because polymerization proceeds only in the presence of light, whereas thermal methods can be started but not stopped once they are underway,” Lacôte says.

Although UV- or blue-light-based photopolymerization systems have been established, they have limitations. Short-wavelength radiation is scattered when the particle size becomes close to the radiation wavelength, making latexes with particle sizes larger than the incoming wavelengths difficult to produce. In addition, UV light is highly energy-intensive, not to mention hazardous to the humans working with it.

Using Visible Light

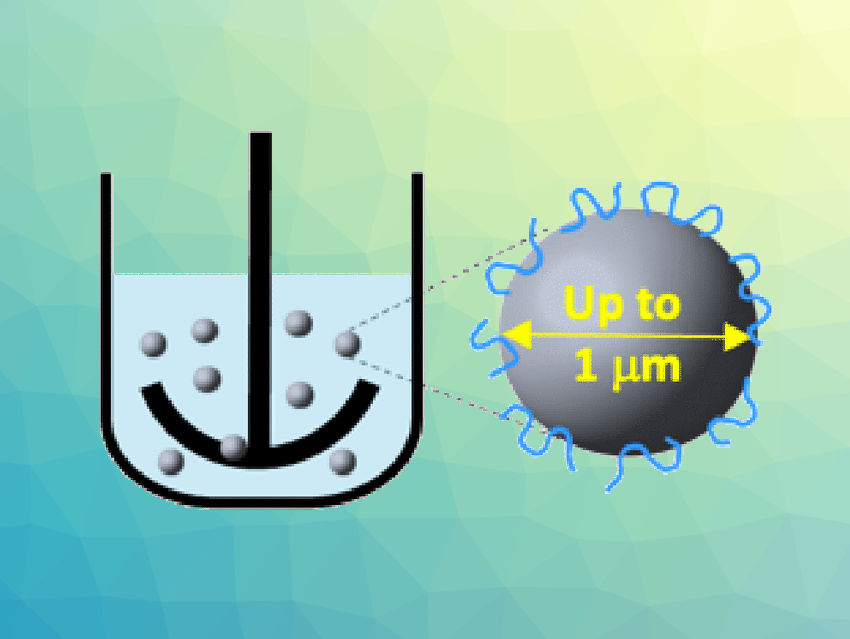

The researchers, therefore, developed a fine-tuned chemical initiation system that responds to standard LED light in the visible range. This polymerization system, which is based on an acridine dye, stabilizers, and a borane compound (pictured below), was the first to overcome the “300-nanometer ceiling”—i.e., the size limit of UV and blue-light-driven polymerization in a dispersed medium. As a result, for the first time, the team was able to use light to produce polystyrene latexes with particle sizes greater than one micrometer and with highly uniform diameters.

The team suggest applications well beyond polystyrene. “The system could potentially be used in all areas where latexes are used, such as films, coatings, supports for diagnostics, and more,” Lacôte says. In addition, the polymer particles could be modified with fluorescent dyes, magnetic clusters, or other functionalities useful for diagnostic and imaging applications. The team says that a broad range of particle sizes spanning the nano and micro scales could be accessible “simply by tuning the initial conditions.”

- Visible‐Light Initiated Dispersion Photopolymerization of Styrene,

Rémi Canterel, Jacques Lalevée, Elodie Bourgeat‐Lami, Emmanuel Lacôte, Muriel Lansalot,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202309674