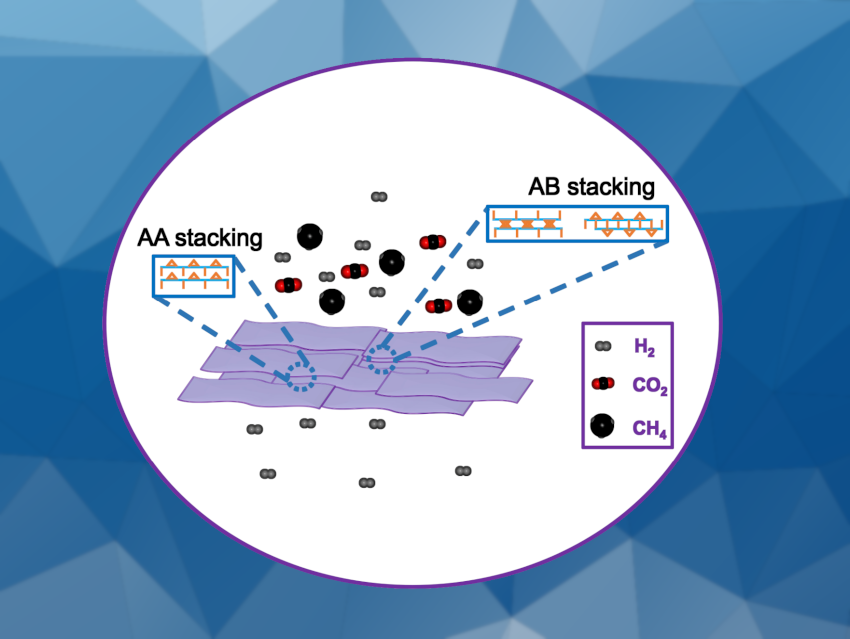

Hydrogen could be a useful alternative fuel to curb CO2 emissions. The commonly used industrial process for hydrogen production, however, gives hydrogen in a mixture with other gases, such as CO2 and CH4, which can be challenging to separate. Membrane separation technology can be promising for this, and 2D material-based membranes made from materials such as graphene oxide or 2D metal–organic frameworks (MOFs) are interesting research targets. The performance of membranes based on 2D MOF nanosheets can be affected by the stacking of the nanosheets, but this effect has not been well-studied, and it is difficult to control nanosheet stacking via traditional methods.

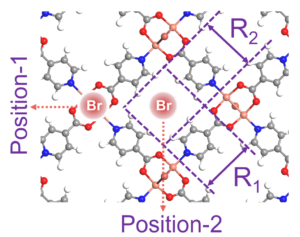

Yanying Wei, South China University of Technology, Guangzhou, China, Haihui Wang, Tsinghua University, Beijing, China, and colleagues have prepared a 2D MOF membrane based on [Cu2Br(IN)2]n (IN = isonicotinato) nanosheets. In this MOF, pairs of copper atoms are bridged by two carboxylate-bonded IN ligands and a bromine ligand, with the remaining coordination position filled by an additional N-coordinated IN ligand. The bromine atoms can adopt one of two specific positions during stacking (pictured below), so that the MOF adopts only AA or AB-type stacking modes in nanosheet membranes, with no positions in between.

The stacking of the MOF nanosheets is controlled by changing the temperatures during drop coating. This allowed the team to investigate the impact of these two stacking modes on the gas separation performance of the membranes. [Cu2Br(IN)2]n was synthesized via hydrothermal reactions, and nanosheets were obtained via ball milling followed by ultrasonic probe treatment. Ultrathin nanosheet membranes were then prepared via drop-coating on porous α-Al2O3 substrates.

The team measured the H2/CH4 separation performance of membranes prepared at different temperatures. The H2 permeance increases with the temperature of drop coating, and the CH4 permeance has a minimum at 90 °C. This results in a maximum H2/CH4 selectivity for a drop coating temperature of 90 °C, where AA stacking dominates.

Optimized nanosheet membranes exhibit high gas separation performances for H2/CH4 (selectivity > 290) and H2/CO2 (selectivity > 190) separation and could provide an approach to environmentally friendly H2 purification.

- Tuning the Stacking Modes of Ultrathin Two‐Dimensional Metal‐Organic Framework Nanosheet Membranes for Highly Efficient Hydrogen Separation,

Shizheng Song, Wei Wang, Yali Zhao, Wufeng Wu, Yanying WEI, Haihui Wang,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202312995