Metal-backboned polymers (MBPs), whose backbone is constructed from metal atoms connected by metal–metal bonds, could be useful materials with interesting electric, magnetic, optic, and thermoelectric properties. One-dimensional nanowires, such as in a metal backbone, can have a lower thermal conductivity and and improved electrical conductivity compared with the bulk material. This makes them interesting for applications in thermoelectric materials, which directly convert thermal energy into electricity.

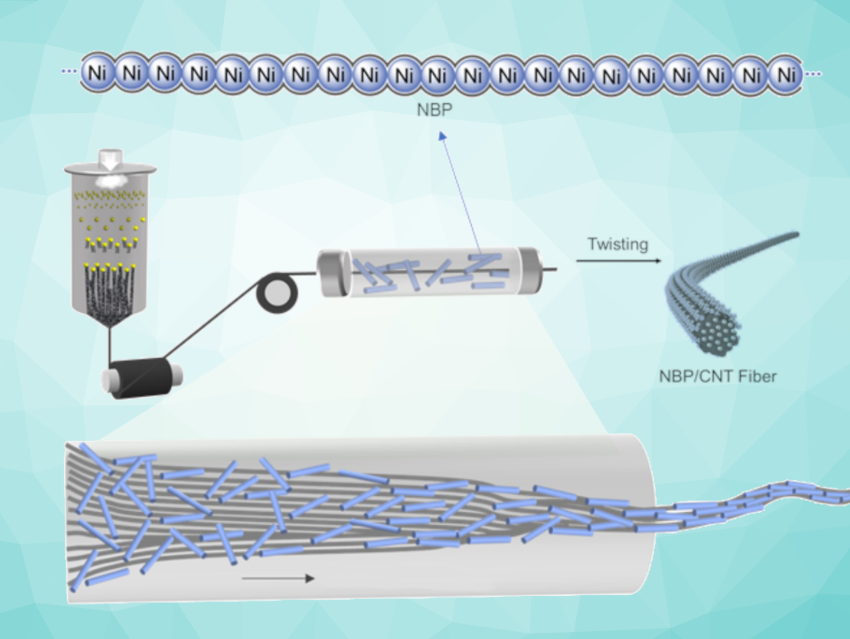

Huisheng Peng, Fudan University, Shanghai, China, and colleagues have prepared a nickel-backboned polymer (NBP)/carbon nanotube (CNT) thermoelectric composite fiber using a shear-induced orientation method (pictured). The fibers could be useful for wearable power devices. The team pulled the CNTs through a dichloromethane solution of the polymer to create NBP/CNT sheets, in which the NBP chains are oriented parallel to the CNTs due to shearing force. Twisting the resulting material then gave NBP/CNT composite fibers.

The developed fibers show increases in the electrical conductivity and the Seebeck coefficient (a measure for the magnitude of an induced thermoelectric voltage in response to a temperature difference) compared with a “bare” CNT fiber. They reached a power factor of 719.48 μW m–1 K–2, which is ca. 3.5 times that of the CNT fiber alone. The team showed that the composite fibers can be integrated into fabrics to harvest thermal energy from the body, generating an output voltage of 3.09 mV at a temperature difference of 8 K between the body and the environment. This could be useful to build flexible, wearable power supplies that work with body heat.

- High‐performance thermoelectric fibers from metal‐backboned polymers for body‐temperature wearable power devices,

Ning Wang, Kaiwen Zeng, Yuanyuan Zheng, Hongyu Jiang, Yibei Yang, Yifeng Zhang, Dingke Li, Sihui Yu, Qian Ye, Huisheng Peng,

Angew. Chem. Int. Ed. 2024.

https://doi.org/10.1002/anie.202403415