Yadong Yin, University of California, Riverside, USA, and colleagues have developed a coating material that can be written on using UV light and the writing erased again using oxygen. Changes to rewritable paper could help reduce paper waste in a wide variety of applications. The material is made from three non-toxic components and is produced in a single synthesis step.

Doped TiO2 Nanocrystals

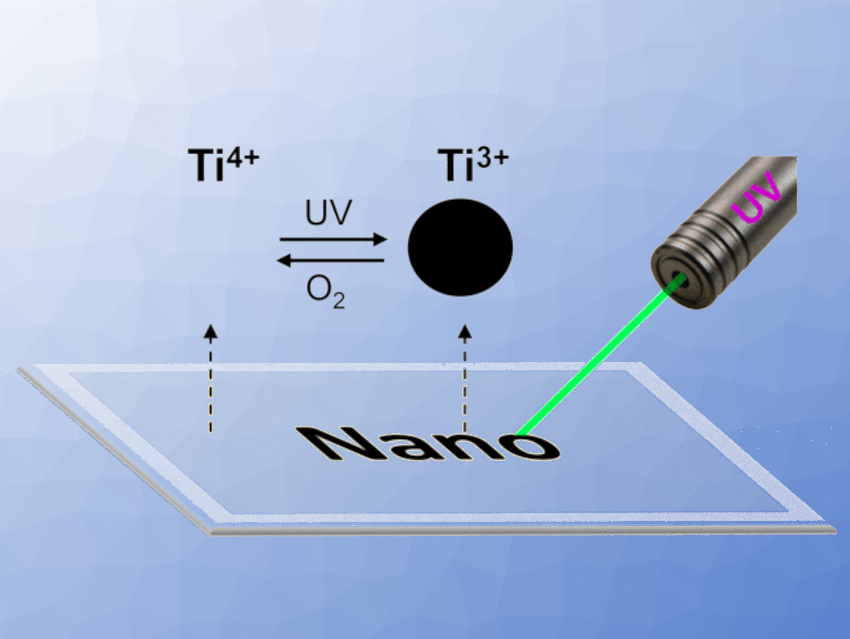

The team focused on titania (TiO2) nanocrystals to produce a light-sensitive, rewritable system. Nanocrystalline TiO2, a semiconductor, darkens when irradiated with ultraviolet (UV) light due to charge separation and the reduction of titanium atoms. Critically, the color change is not permanent because oxygen in the air reoxidizes the titanium and causes a return to transparency.

The researchers concentrated on sustaining the color change for a longer period of time. They used nitrogen as a dopant, which they obtained from urea, and decorated the crystals with diethylene glycol. This substance, added to the synthesis as a solvent, also played a crucial role in the color change; the team noted that it scavenged excess electron holes and so delayed reoxidation and a return to the transparent state.

Rewritable Surfaces

When applied to glass or paper, the nanocrystals formed a uniform coating that could be written on using UV light. All that was needed to produce the writing was 30 seconds of illumination with a light source at a wavelength of less than 400 nm. The team emphasized that it was not necessary to use a strong light source; lamps in the power range of LEDs were sufficient to produce a high level of contrast on the material.

The team explored two light-writing methods. First, they produced patterns or printed text by illuminating the paper or glass substrate through a photomask. They also produced freehand writing using a laser pen. Both options gave a high-contrast pattern that was stable for many hours and could either be erased by heating or faded slowly because of oxidation. The team points out that extending the life of the printing is possible by covering the film surface with a protective layer of a non-toxic polymer, reducing its exposure to oxygen.

The main advantage of the system produced by the team is its reusability. Up to 50 write-erase cycles could be completed without any notable loss of contrast. This means that the technology could be applied in a number of fields where reusable/rewritable surfaces are required; for example, daily transport tickets, information boards, data storage, or sensor technology. The researchers highlight the simple production method using common, non-toxic starting materials and the high degree of compatibility with other materials.

- Rapid High‐Contrast Photoreversible Coloration of Surface‐Functionalized N‐Doped TiO2 Nanocrystals for Rewritable Light‐Printing ,

Rashed Aleisa, Ji Feng, Zuyang Ye, Yadong Yin,

Angew. Chem. Int. Ed. 2022.

https://doi.org/10.1002/anie.202203700

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)