BASF has successfully commissioned the steam cracker at its newly built Verbund site in Zhanjiang, South China, as scheduled. This is the first cracker in the world to use 100% renewable energy to drive its main compressors. Using electricity (eDrives) instead of steam-driven turbines for the cracker’s compressor machines avoids on-purpose steam production in fossil-fuel–powered boilers and enables equilibrium in the steam balance for the entire Verbund.

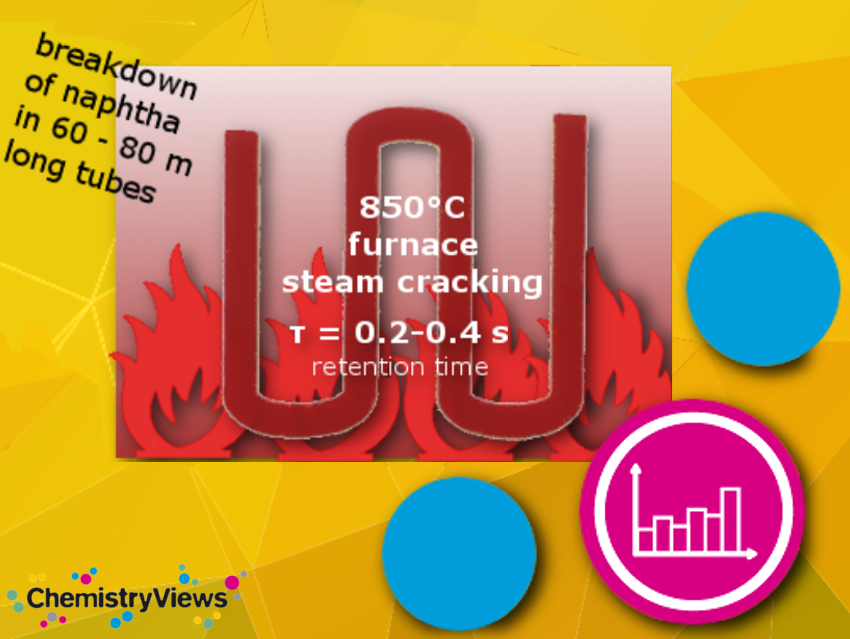

As the heart of the Verbund, the steam cracker supplies essential basic chemicals such as ethylene and propylene to multiple on-site plants. It is the starting point for many chemical value chains: long-chain hydrocarbons such as naphtha or butane are cracked with the help of steam. The ethylene capacity amounts to one million metric tons per year.

Moreover, following the recent successful start-up of several propylene downstream plants, BASF has safely brought into operation the plants for ethylene oxide, ethylene glycol, and polyethylene. Zhanjiang will be BASF’s third-largest Verbund site worldwide, after Ludwigshafen in Germany and Antwerp in Belgium, and will serve as a model for sustainable production in China and globally. For example, the site will be supplied entirely with electricity from renewable sources.

Products from BASF’s Zhanjiang Verbund site will primarily supply customers in the Chinese market, the largest and fastest-growing chemical market in the world, the company says.

- BASF SE, Ludwigshafen, Germany

Also of Interest

BASF, SABIC, and Linde begin construction; technology can reduce CO2 emissions by at least 90 % compared to conventional steam crackers

Learn from this picture how a steamcracker works