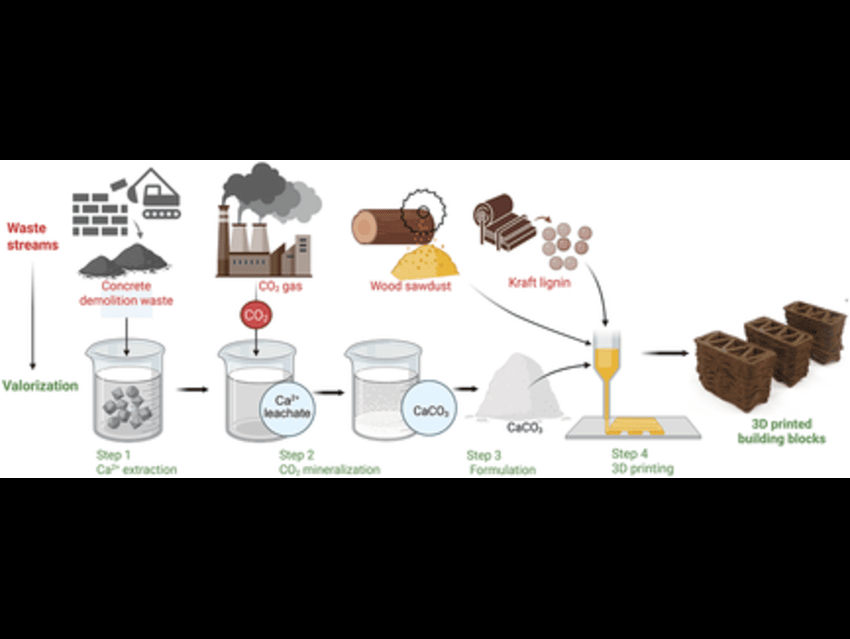

Reducing CO₂ emissions from the building sector is critical, as it consumes 40% of global raw materials and 35% of energy. Yong Ding and Ingo Burgert, Institute for Building Materials, ETH Zürich, Switzerland, and their team tackled this challenge by developing a scalable method to turn demolition waste and biomass byproducts into sustainable building materials while capturing CO₂.

The team extracted calcium ions from recycled concrete aggregates (RCA), which contain calcium silicate hydrates, calcium hydroxide (Ca(OH)₂), and calcium carbonate (CaCO₃). They tested various leaching agents, including deionized water, hydrochloric acid, and ammonium salts. Ammonium acetate proved most effective, yielding 7,857 mg/L of Ca²⁺, 120 times more than water, without releasing stored carbon. The resulting alkaline leachate (pH ~10) was ideal for mineralization.

CO₂ gas was bubbled into the calcium-rich solution, triggering a series of reactions in which CO₂ dissolved in water, formed carbonic acid, which then dissociated into carbonate ions that reacted with Ca²⁺ to precipitate CaCO₃. The process removed over 99.9% of Ca²⁺, and Fourier transform infrared spectroscopy confirmed calcite as the dominant mineral phase.

To create printable ink, the researchers blended the CaCO₃ with kraft lignin, a renewable byproduct from wood pulping, and water to form a mineral binder. Lignin improved dispersion and adhesion to wood. Rheological tests showed the binder was shear-thinning and flowed easily. Mixing in sawdust (10–20 wt%) produced stable inks, with 18 wt% sawdust offering optimal printability. After drying, the printed composite contained 29 wt% CaCO₃, 29 wt% lignin, and 42 wt% sawdust. The team successfully printed modular structures with consistent quality.

Mechanical tests revealed moisture sensitivity: at 25% relative humidity (RH), compressive strength reached 11 MPa; at 95% RH, the material absorbed water and showed sponge-like behavior. A cradle-to-gate life cycle assessment showed a global warming potential (GWP) of −0.85 kg CO₂-equivalent per kg of material, thanks to biogenic carbon storage. Compared to conventional materials like medium-density fiberboard and polyurethane foam, the printed composite had the lowest environmental cost.

By combining CO₂ capture, waste valorization, and additive manufacturing, the researchers demonstrated a closed-loop strategy for decarbonizing construction. Future work could focus on improving moisture resistance and scaling the process for industrial use.

- Valorization of demolition waste and biomass byproduct into sustainable building materials via carbon mineralization and 3D printing

Yong Ding, Robert Oswin Kindler, Tianyu Cen, Xiulin Chen, Zhidong Zhang, Ueli Angst, Christian Moretti, Ingo Burgert

Chem. Methods 2025

https://doi.org/10.1002/cmtd.202500007