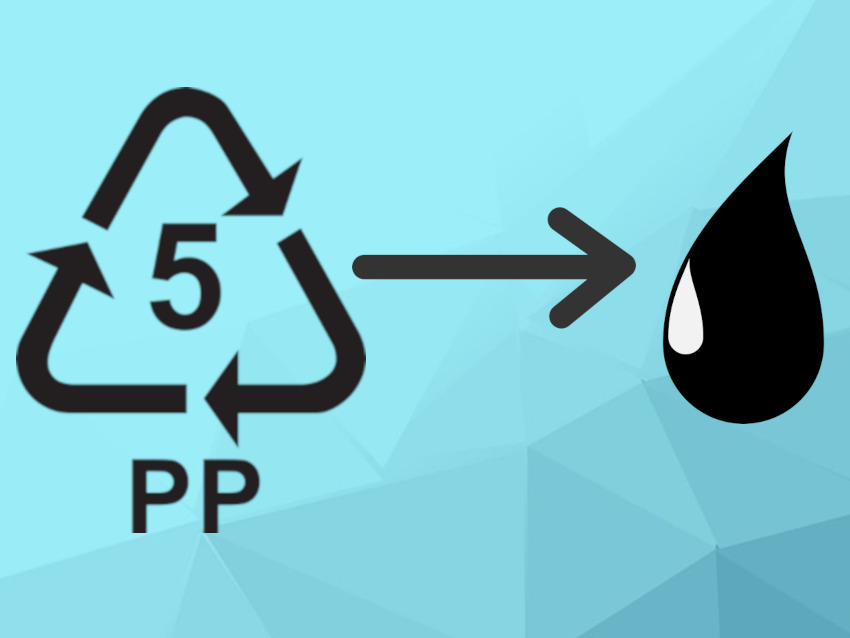

Plastic waste is an important environmental problem because many polymers cannot be degraded well in the environment. Some polymers can be recycled and used as raw materials for new products, but the quality of the material can worsen in this process. Therefore, recycled plastics can often only be used for less valuable products and the number of cycles is limited. An alternative approach is the chemical degradation of polymeric materials to low-molecular-weight products that can be used in other applications and replace precursors derived directly from fossil resources. One method for this is the degradation of polyolefins in the presence of hydrogen and a heterogeneous catalyst.

Matthew P. Conley, University of California, Riverside, USA, and colleagues have developed a method for the degradation of isotactic propylene using hydrogen and a tantalum hydride catalyst immobilized on sulfated alumina. The reaction was performed in molten polypropylene at 200 °C under 1 atm of hydrogen gas. After 24 h, the polymer was converted to the target branched alkanes containing 11–30 carbon atoms in 70 % yield. Additionally, some lighter hydrocarbons were formed.

The use of higher hydrogen pressures led to lower yields of the desired liquid alkanes. The stereochemical information contained in the isotactic polypropylene is lost in the produced alkanes, but unconverted polymer retains its tacticity. The degradation method does not work well if polyethylene is used instead of polypropylene because the involved β-alkyl elimination reaction is favored by the more sterically crowded environment present in polypropylene. Thus, carefully tailored catalysts are needed for the degradation of different polymers depending on their structure and chemical properties.

- Polypropylene Degradation Catalyzed by Tantalum Hydrides Supported on Sulfated Alumina,

Jiaxin Gao, Lingchao Zhu, Matthew P. Conley,

ACS Catal. 2023.

https://doi.org/10.1021/acscatal.3c02642