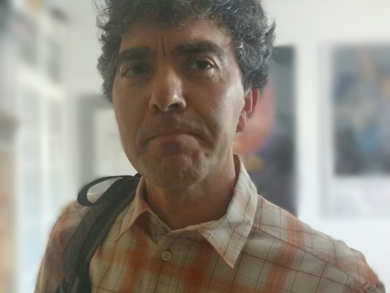

Dr. Arlette Itken-Fuder, Senior Associate Editor of the European Journal of Inorganic Chemistry, talks to Professor Joaquín Coronas, Universidad de Zaragoza, Spain, about his article on MIL-68(Al) films on cylindrical alumina supports, which was published recently. This study is about optimizing the attachment of metal–organic frameworks (MOFs) on alumina supports using various linkers. The MOFs could then be used for separation in industrial applications.

Professor Coronas, you have explored the interaction of MOF films with alumina supports. What was the inspiration for this study?

MOFs are microporous and crystalline hybrid organic–inorganic materials with separation functions similar to those of zeolites but with much higher chemical and structural flexibility. For instance, MOF membranes can be extremely useful to separate CO2-containing mixtures related to possible carbon capture technology. In addition, these membranes could be used to separate a number of different mixtures both in the gas phase (air purification, natural gas upgrading, etc.) and in the liquid phase (pervaporation and membrane reactors).

Your results showed that functional groups forming hydrogen bonds helped to anchor the polymer on the support. What is the significance of these results?

These results mean that it would be possible to prepare MOF membranes in robust and cheap commercial alumina supports. This would facilitate a future up-scaling of membrane-related processes based on MOFs.

Which linking agents did you use?

We knew the difficulties of preparing the MOFs directly on the alumina supports. Thus, we hypothesized that modification of the supports using amorphous silica, the zeolite silicalite-1, and the polysaccharide chitosan as linking agents would make them more compatible with MOF synthesis.

What is the broader impact of this paper for the scientific community?

We believe the knowledge resulting from this study may help other researchers to find the way towards a deeper understanding regarding the direct synthesis of MOFs on several types of supports, particularly on commercially available porous alumina. Beyond the membrane application, this can also be useful for other applications related to coatings for selective porous materials.

Why was your attention focused on this particular area?

We have been working on selective membranes, inorganic and organic, and with selective materials, zeolites and related materials, as well as MOFs, for more than 20 years. We thought MOFs could overcome the difficulties in preparation and performance associated with other materials, and we found an objective and solid way of enhancement.

How long did this investigation take?

This is part of a Ph.D. thesis that started about four years ago. This was the most difficult part of the study, since alumina supports, given their broad macroporosity and relative chemical inertness, are difficult to directly implement as membrane supports. The Ph.D. candidate, Ms. Adelaida Perea-Cachero, will defend her thesis before this summer.

Which part of the work proved the most challenging?

The most challenging part was to obtain defect-free membranes of high quality for separation applications after we identified the optimal conditions to attach the MOF on the modified alumina surface. This will require future work.

The article they talked about

- Enhancement of Growth of MOF MIL-68(Al) Thin Films on Porous Alumina Tubes Using Different Linking Agents,

Adelaida Perea-Cachero, Pablo Calvo, Enrique Romero, Carlos Téllez, and Joaquín Coronas,

Eur. J. Inorg. Chem. 2017, 2532–2540.

DOI: 10.1002/ejic.201700302