Metal-organic frameworks (MOFs), or porous coordination polymers, are materials of emerging practical use in various fields. However, their applicability in sensing and drug delivery applications is oftentimes hindered by the size of the MOFs. Bigger MOFs (in the µm size range) have slower response times due to high path lengths, which reduce the ease of the uptake and release of compounds. Strategies to create nanoscale MOFs include the synthesis in a confined environment to be able to control the MOFs’ growth direction and dimension.

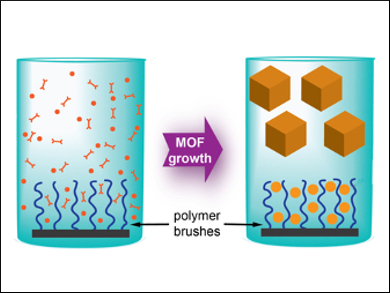

Ning Zhang, Chinese Academy of Sciences, Changchun, China, and colleagues have used polymer brushes based on poly(tert-butyl methacrylate) (PBMA), which are grown on a silicon substrate, for the fabrication of surface-tethered MOF-5 (MOFs composed of Zn and terephthalic acid). The carboxylic groups in PBMA serve as nucleation sites for the MOF-5 (process pictured). The researchers characterized the MOFs using infrared (IR) spectroscopy, powder X-ray diffraction measurements, atomic force microscopy (AFM), and scanning electron microscopy (SEM).

The team showed that the MOFs grown on polymer brushes had a diameter between 18 nm and 89 nm (at 2 min and 20 hours of nucleation, respectively), which makes them an order of magnitude smaller than MOFs grown directly from solution. Furthermore, the researchers were able to control the size of the MOF by tuning the density of carboxylic groups in the polymer brushes or by changing the spacing of the polymer brushes on the surface of the silicon substrate. This strategy was also applied to other compositions (e.g., MIL-125) showing its applicability in fabricating surface-attached MOFs.

- Controlled Growth of Metal-Organic Frameworks on Polymer Brushes,

Liman Hou, Mingdong Zhou, Xiaozhe Dong, Lei Wang, Zhigang Xie, Dewen Dong, Ning Zhang,

Chem. Eur. J. 2017.

DOI: 10.1002/chem.201703827