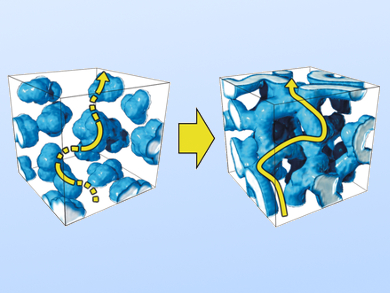

Composite polymer electrolytes are emerging as promising alternatives to liquid electrolytes in lithium-ion batteries. Nanofillers in polymer matrices often improve mechanical and electrochemical performances. However, the agglomeration of nanofillers means that the properties of these composite electrolytes are not suitable for practical applications.

Guihua Yu, The University of Texas at Austin, USA, and colleagues have developed a 3D nanoporous ceramic framework for high-performance composite polymer electrolytes. The Li0.35La0.55TiO3 (LLTO) framework (pictured right) was prepared by a gelation process to form a hydrogel and subsequent heat treatment. The 3D interconnected framework design can avoid agglomeration issues and can be used as 3D nanofillers for the polymer matrix.

The integration of this LLTO framework into a polymer, poly(ethylene oxide) (PEO), enhances its mechanical properties and results in a flexible composite film. The 3D framework improves the electrochemical and thermal stability of composite electrodes. The continuous interphase between the 3D framework and the polymer leads to improved Li-ion conductivity close to 10–4 S/cm at 25 °C. This structural design and synthesis method could serve as a new approach toward advanced solid electrolytes for next-generation Li-ion batteries.

- A 3D Nanostructured Hydrogel Framework-Derived High-Performance Composite Polymer Lithium-Ion Electrolyte,

Jiwoong Bae, Yutao Li, Jun Zhang, Xingyi Zhou, Fei Zhao, Ye Shi, John B. Goodenough, Guihua Yu,

Angew. Chem. Int. Ed. 2018.

https://doi.org/10.1002/anie.201710841