An Entirely New Way to Print Objects

Printing is centuries old. It commonly involves the transfer of inks onto a solid to form objects like letters, symbols, or graphics. This solid is traditionally paper, but almost every solid material has been a substrate for printing at one time or another. Might it be possible, however, to print onto a liquid?

If the answer to this question turns out to be yes, it would provide access to self-supporting, self-contained objects which do not need to be separated from a solid substrate—a final step that is necessary when objects are printed to a solid. This would open up an entirely new way to print objects that might have applications, e.g., in microfluidics.

Werner Goedel, Chemnitz University of Technology, Germany, and colleagues have prepared such self-supporting objects by inkjet printing of a photo‐curable ink onto a water surface, followed by irradiation with ultraviolet (UV) light and lift‐off. The challenge is not to apply continuous layers of ink on to a water surface, this has already been done very successfully in traditional crafts like paper marbling. The challenge is to print onto a more or less bare water surface and obtain self-contained structures not connected to each other—like lines of defined width, full-tone squares, and delicate structures with non-uniform line width, edges, and openings. These floating solid structures would then be easily lifted off the water as individual objects.

Timing is Everything

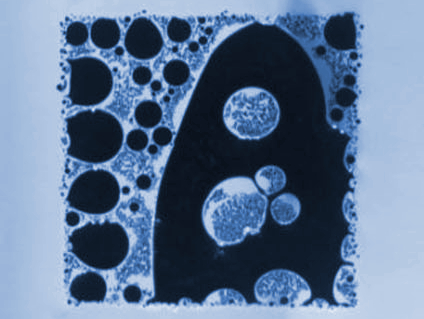

Using an inkjet printer, the team printed a liquid non-volatile photo-curable ink on to a water surface covered with particles, like a layer of dust. Irradiation with ultraviolet light, timed precisely, allows the structures to be solidified and subsequently lifted off from the surface of the water. The researchers explain that the key to their success was working out how to control convection, spreading, and de-wetting of the ink from the water surface. This involves timing the UV irradiation step very precisely but also controlling the mobility of the water surface and the long and short-range interactions between the printed ink and the water substrate.

As the name suggests, inkjet printing is a form of non-contact printing. Tiny jets controlled by a computer essentially squirt tiny droplets of ink on to a substrate, usually a sheet of paper. The inkjet printer is now an almost ubiquitous desktop device in our homes and the workplace. Over the years though, scientists have experimented with different “inks”, using all kinds of non-conventional substances like wax, polymeric semiconductors and light emitters, inorganic semiconductors, metals, ceramics, photocatalysts, DNA, and even living cells to print patterns and flat objects on to a wide range of surfaces, including metal, semiconductor, glass, ceramics, plastics, and so on.

Thin functional patterns can be produced and then given three-dimensional features by overprinting with the same or other “inks”. The modern inkjet printer has allowed people to make flat and three-dimensional objects and to pattern surfaces in a way that was almost entirely beyond the capabilities of such an inexpensive piece of equipment just a couple of decades ago.

Lift and Separate

Common to all of those techniques, is the concept that the printed material works in situ on the substrate or is otherwise carefully lifted off and then applied to another surface. Goedel and his colleagues have demonstrated that this limitation and complication can readily be overcome using their technology. The approach takes some inspiration from ancient paper marbling techniques. It has one important difference though: it produces self-contained and self-supporting “objects” on the water surface that are not connected to each other.

The unique trick in the team’s approach: they obtain the best results if they cover the surface of the water with a monolayer of particles. This layer is stiff, rough, has a refractive index higher than water, and is significantly thicker than a monolayer of surfactants. These properties help to keep the structures in place between printing and solidification. Yet, the monolayer of particles is non-contiguous and, thus, falls off the moment the solid structures are “harvested”.

The initial proof of principle generates esthetically pleasing objects, but the team has high hopes for their technique: “We envision that, in the future, the technique proven here may be used to generate self-supporting, self-containing, and functional objects.”

- Inkjet Printing of Self-Supporting and Self-Contained Structured Objects Onto Liquid Surfaces,

Werner A. Goedel, Kerstin Gläser, Dana Mitra, Robert Thalheim, Peter Ueberfuhr, Jens Hammerschmidt, Reinhard R. Baumann,

Adv. Eng. Mater. 2019.

https://doi.org/10.1002/adem.201900227