For muscular aches, pains, and injuries, anti-inflammatory drugs are usually the go-to recommendation of healthcare workers. But in parallel to that, an ice-pad for acute injury and a heated pad for longer-term treatment is commonly used. Off-the-shelf thermotherapy pads that a patient might obtain are often “one size fits all” or at best small-medium-large. This is less than ideal given just how different our bodies can be in terms of size and stature.

On‐Demand Printing of Wearable Thermotherapy Pad

Jin‐Woo Han, NASA Ames Research Center, Mountain View, CA, USA, and colleagues have developed thermotherapy pads that can be made on demand to suit a patient’s exact needs. They suggest that a printed heat pad produced by simple and low-cost fabrication can be used to make wearable medical devices for personal thermotherapy.

The underlying principles of heat therapy for pain are based on the existence of a complex network of nerve endings in our body. When these nerve endings are stressed through injury or disease, they send signals to the brain perceived as pain. Moderate heat can modulate this signaling and ease the pain. In addition, it can relax muscles, increase beneficial blood flow, and reduce inflammation. There is also the assumed psychological effect associated with the comfort of warming to consider.

Preparing the Custom‐fit Heat Pads

To prepare their heat therapy pads, the researchers start with medical-grade tape. They coat this tape with silica nanoparticles as an ink-absorbing layer. The silica particles change the surface properties of the medical tape from hydrophobic to hydrophilic. Chloride ions are added as a chemical sintering agent.

The team then uses nothing more sophisticated than commercial inkjet printing technology to print stable heater patterns on to the tape using ink that contains silver nanoparticles as the active component. Their approach precludes the need for any additional thermal sintering of the printed materials, as the additives take care of that in the process. The chemical sintering of the nanoparticles is caused by desorption of the polymer from the silver surface as it is replaced by chloride ions. The silver nanoparticles then come into close contact, enabling them to coalesce or sinter.

Laboratory tests demonstrated the electrical and thermal integrity of the printed heating device. The team reports that it is stable in operation and stays reliably within a defined temperature even when run continuously for a month and with various bending conditions to simulate everyday wear and tear by a patient.

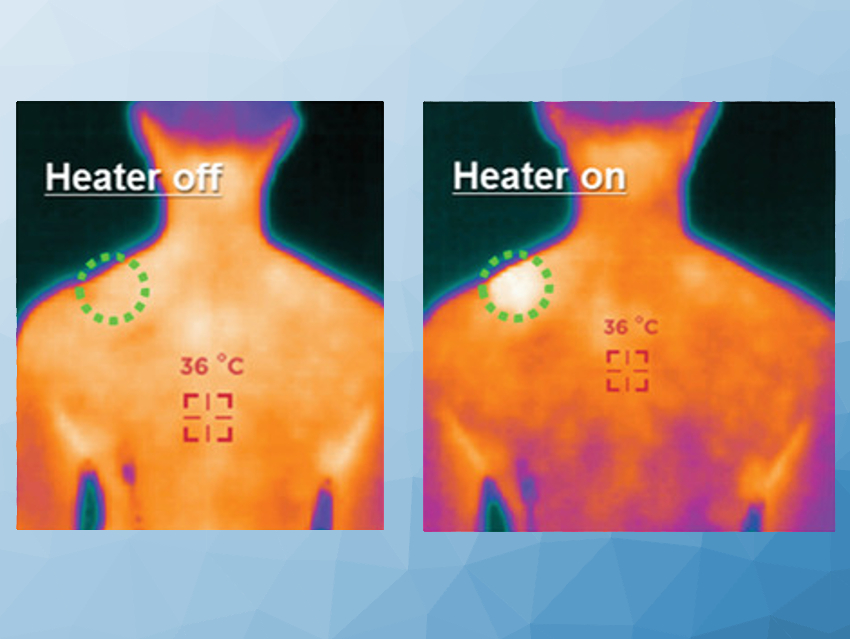

The final step to make the pads tailormade was to carry out a three-dimensional scan of the patient’s body, or at least the part of their body that requires the heat therapy, and to fabricate a suitable pad to which the heater tape could be added. The specific proof of principle involved customizing a heat pad in this way for a device to be fitted to a patient’s shoulder (pictured). The benefits of the thermotherapy could then be verified somewhat objectively using electroencephalography, the team adds, and subjectively by asking the patient if they are getting any relief from pain and discomfort.

- On‐Demand Printing of Wearable Thermotherapy Pad,

Dong‐Il Moon, Gintarė Plečkaitytė, Taejun Choi, Myeong‐Lok Seol, Beomseok Kim, Dongil Lee, Jin‐Woo Han, M. Meyyappan,

Adv. Healthcare Mater. 2020.

https://doi.org/10.1002/adhm.201901575