Separation processes using membranes are widely applied in different industries. One of the main problems of this technology is fouling. Over time, deposits accumulate on the membrane surface and clog the pores. This reduces the membrane’s throughput. Different cleaning methods can be used to remove the fouling, however, methods such as ultrasonic cleaning can damage the membrane.

Zihim Lam and colleagues, Karlsruhe Institute of Technology (KIT), Germany, have investigated the cleaning effect of a high-pressure jet of water on a polymeric microfiltration membrane. The team tested different pressures, durations, and angles for the jet, and compared the resulting throughput rates to the original membrane.

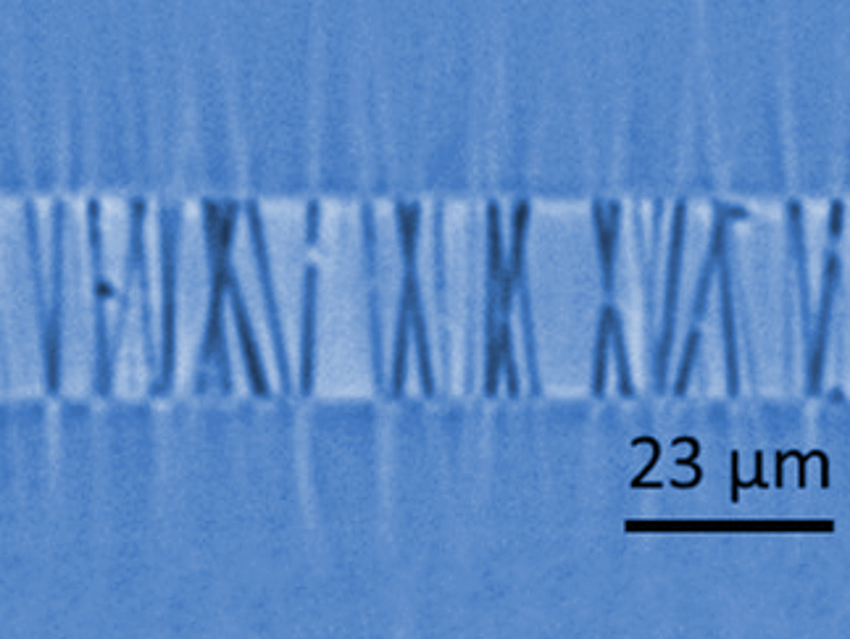

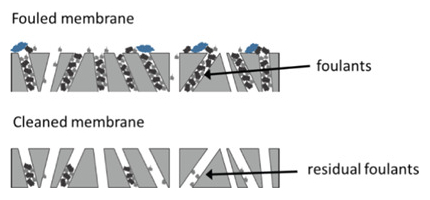

The membrane was not significantly damaged by the process, which was indicated by similar pore size distributions before and after cleaning. The membrane also retained good mechanical stability. Experiments with artificially fouled membranes showed that a high jet pressure of 130 bar results in an improved fouling removal. The higher pressure leads to higher velocities and a higher wall shear stress. This removes the particles adhering to the surface or the pore-channel walls. A longer cleaning duration also increased the fouling removal, but only up to 10 s. And finally, an angle of 70° was the most effective, possibly because many of the pore channels (pictured) have declination angels between 70 and 80°.

Under these conditions, about 80 % of the initial throughput of the membrane was restored. Overall, it can be concluded that high-pressure jet cleaning is an effective method for the mechanical cleaning of microfiltration membranes.

- High-Pressure Jet Cleaning of Polymeric Microfiltration Membranes,

Zihim Lam, Harald Anlauf, Hermann Nirschl,

Chem. Eng. Technol. 2020.

https://doi.org/10.1002/ceat.201900449