Composite materials containing metal-organic frameworks (MOFs) are rare because the crystalline frameworks do not form homogeneous dispersions and are not easy to integrate into supporting structures. However, scientists have found a surprisingly straightforward way to process a zeolitic imidazolate framework so that it forms stable particle dispersions and forms composite membranes with polymers.

These new materials might be useful for gas separation technologies based on permeable membranes or fluid systems. Functional coatings and textiles are other possible fields of application.

Gas Adsorption in Crystalline Porous Structures

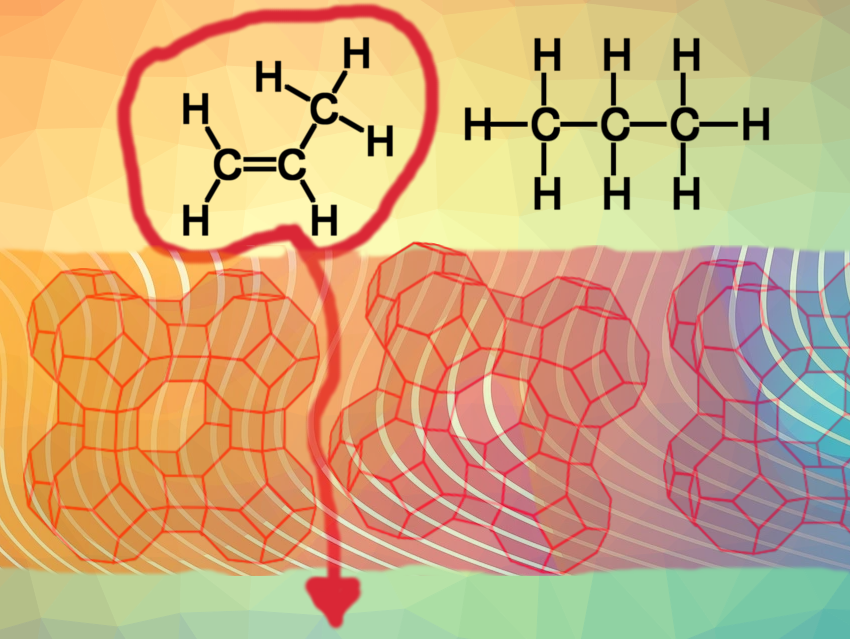

Guest molecules enter the MOF framework, and the pore size, geometry, and nature of the docking sites define their uptake and adsorption capacity. MOFs can be designed to adsorb small hydrocarbon molecules, a highly anticipated feature for petrochemical gas separation.

Traditionally, the petrochemical industry purifies light hydrocarbon gases by distillation processes, which consume a lot of energy. MOF adsorption would work under much milder conditions, but the current materials still have a long way to go to meet the industry’s needs for robustness, longevity, specificity, and price.

MOFs are solid, rigid structures that withstand further processing. Unlike polymers, which are also solids but form colloids and dispersions and interact with their environment, it is virtually impossible to make MOF particles more reactive. This means they are not particularly practical for use as a composite material, gel, solute, or membrane component in any separation technology.

Adding Processability

This could be about to change. A team of scientists lead by Alexander Knebel, Leibniz University Hannover, Germany, Anastasiya Bavykina, Yury Lebedev, and Jorge Gascon, King Abdullah University of Science and Technology (KAUST), Thuwal, Saudi Arabia, reports the processing of a modified crystalline MOF, a zeolitic imidazolate framework called ZIF-67, either to form a “porous liquid” to adsorb gas molecules or to build mixed matrix membranes for separating propylene from propane.

To make the modified ZIF-67, the researchers mixed the crystalline particles with N-heterocyclic carbenes (NHCs), a class of surface modifiers known for their affinity to unsaturated metal sites. In the case of ZIF-67, these sites consisted of cobalt ions, and the NHC ligands replaced a fraction of the imidazolate ligands occupying these sites at the particle surface.

Porous Liquids

Like polymer particles given soluble groups at their surface, the surface-modified MOF particles—called ZIF-67-IDip after the type of NHC—formed stable dispersions in organic solvents. As the dispersant MOF is porous (unlike most polymers), such dispersions are called porous liquids.

However, a liquid can only be referred to as “porous” if it contains particles with unoccupied pores. With its low pore size of 3.4 Å, the ZIF-67 framework excludes large organic solvents such as cyclohexane and mesitylene. As the mesitylene-based dispersions took up much more gas molecules than the neat solvent, the researchers concluded the dispersions were true porous liquids.

They also observed that smaller solvent molecules such as methanol blocked the pores, and these dispersions did not adsorb more gas than the neat solvent. In contrast, when a mixture of methane and propylene was bubbled through a column filled with the mesitylene dispersion, propylene was retarded, hinting on the gas separation abilities of these MOF-based dispersions.

Permeable Composite Membranes

However, gases separate better in porous solids than in porous liquids. Gas separation technologies are often based on permeable membranes. Mixed matrix membranes consist of a supporting polymer with embedded separation compounds. To prepare such a composite membrane, the researchers mixed either the unaltered ZIF-67 or the ZIF-67-IDip particles in a polyimide-based membrane. The unaltered MOF version agglomerated and made the membrane brittle. In contrast, ZIF-67-IDip formed a homogeneous matrix with the polymer, and the resulting membrane was reported by the scientists to be tough and stable.

The integrated membrane also demonstrated improved permeability for propylene and improved selectivity of propylene over propane, when compared to the membrane alone and many other separation materials. However, the team admits that the achieved filling level of under 50 % would not allow for great leaps in performance and want to improve it.

- Solution processable metal-organic frameworks for mixed matrix membranes using porous liquids,

Alexander Knebel, Anastasiya Bavykina, Shuvo Jit Datta, Lion Sundermann, Luis Garzon-Tovar, Yury Lebedev, Sara Durini, Rafia Ahmad, Sergey M. Kozlov, Genrikh Shterk, Madhavan Karunakaran, Ionela Daniela Carja, Dino Simic, Irina Weilert, Manfred Klüppel, Ulrich Giese, Luigi Cavallo, Magnus Rueping, Mohamed Eddaoudi, Jürgen Caro, Jorge Gascon,

Nature Materials 2020.

https://doi.org/10.1038/s41563-020-0764-y