Hideyuki Nakanishi, Kyoto Institute of Technology, Japan, and colleagues have prepared nanoporous palladium (Pd) from Pd nanocrystals by the elimination of stabilizers. The Pd nanocrystals are catalytically inert. However, the resulting nanoporous Pd has a bimodal pore structure with an extensive surface area, and its surfaces are electrochemically accessible and show higher catalytic activity toward ethanol electrooxidation than that of the commercial Pd black catalyst (∼2 and ∼3 times higher catalytic activities per unit ECSA and Pd mass, respectively).

The team used Pd nanocrystals with an average diameter of 2.9±0.3 nm. Agglomerates of Pd nanocrystals were prepared by adding methanol to the crude nanocrystal dispersion in toluene and thus precipitating the nanocrystals. Then, wet Pd nanocrystal agglomerates without drying were directly transferred to an excess of 2-propanol maintained at 60 °C and exposed to the solvent for 2 h. This procedure caused the Pd nanocrystals to transform into a different type of Pd material that had a high tolerance to hydrophobic solvents such as toluene. This characteristic was in sharp contrast to that of the initial Pd nanocrystals, which were readily and homogeneously redispersed in the same hydrophobic solvents.

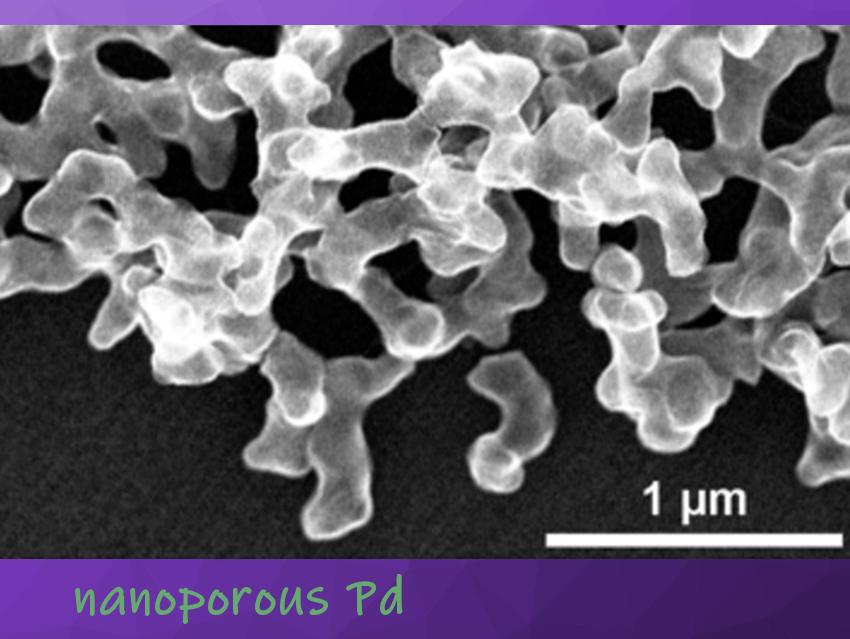

The structure of the resulting Pd was analyzed using scanning electron microscopy (SEM). The SEM images revealed that the Pd nanocrystals structurally evolved into a three-dimensional nanoporous structure. The researchers assume that this structural evolution is due to the surface diffusion of Pd atoms, which was caused by stripping stabilizers from Pd nanocrystals in 2-propanol.

The atomic surface structure can be sensitively altered by the preparation temperature and solvent in contact with Pd atoms during the structural evolution of the Pd nanocrystals, thereby increasing the catalytic activity of the nanoporous Pd. The researchers expect this method to be a new alternative for producing electrochemically active nanoporous Pd as it is simple and available for mass production.

- Metastable Nanoporous Palladium Evolving from Palladium Nanocrystals,

Satoshi Teraji, Sadaki Samitsu, Qui Tran-Cong-Miyata, Tomohisa Norisuye, Hideyuki Nakanishi,

ChemNanoMat 2021.

https://doi.org/10.1002/cnma.202100299