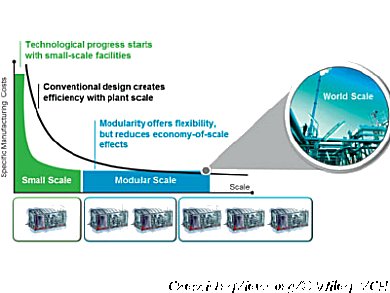

Future chemical production is determined by globalized, volatile markets with increased quality demand for specialty products. A faster time-to-market is necessary as well as an efficient and safe production process. The increasing product variety calls also for more flexible production plants which can produce small amounts as well as up to several hundred tons per year.

According to Thomas Bieringer, INVITE GmbH, Leverkusen, Sigurd Buchholz, Bayer Technology Services (BTS) GmbH, Leverkusen, and Norbert Kockmann, TU Dortmund University, all Germany, for an optimal plant, the versatility of batch vessels must be combined with the safety, reproducibility, and high transport capabilities of continuous-flow micro-structured equipment. In the F3 project 26 partners from nine countries demonstrated the feasibility of a modular factory which runs process-intensified reactions for small- to medium-scale production in a continuous mode. The research organization INVITE GmbH as Public-Private Partnership between TU Dortmund University and BTS was formed for development and technical validation of modular chemical production containers in various research projects.

The know-how is commercially used in the product Flonamic®, chemical and biochemical reactors for the production of pharmaceuticals, chemicals and biotechnical preparations. One core element of these production concepts are micro‐ and milli‐structured devices assisting continuous‐flow processes due to their superior transport characteristics and small holdup. In small‐scale production concepts, these special devices have to be considered together with conventional technology. The platform concept simplifies the scale‐up process from lab to container scale and beyond on different levels in flow rate, temperature, or other process conditions.

- Future Production Concepts in the Chemical Industry: Modular – Small-Scale – Continuous,

Thomas Bieringer, Sigurd Buchholz, Norbert Kockmann,

Chem. Eng. Technol. 2013, 36 (6), 900–910.

DOI: 10.1002/ceat.201200631