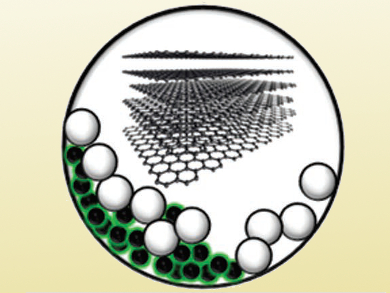

Graphene mass production relies on mechanochemical approaches, such as sonication or high-shear mixing. The yields of such approaches are usually very low (ca. 3 %). An alternative approach is the ball-milling of graphite, either in dry or wet media. However, dry milling tends to produce large amounts of amorphous carbon, and wet milling takes a long time.

Matat Buzaglo, Oren Regev, Ben-Gurion University of the Negev, Beer-Sheva, Israel, and colleagues have developed a ball-milling method in which graphene is protected by solid diluents. This prevents the formation of amorphous carbon by absorbing part of the impact forces. The team ground graphite flakes together with aromatic diluents, e.g., pyrene. After ball-milling, the diluent was dissolved in a suitable solvent and the desired graphene sheets could be isolated by filtration.

The method achieves graphene yields that are an order of magnitude higher than for previous techniques (over 90 %) in under two hours. According to the researchers, the approach could be easily applied to other carbon raw materials as well as for the production of other 2D materials.

- Graphite-to-Graphene: Total Conversion,

Matat Buzaglo, Ilan Pri Bar, Maxim Varenik, Liran Shunak, Svetlana Pevzner, Oren Regev,

Adv. Mater. 2016.

DOI: 10.1002/adma.201603528