Film dewetting is the phenomenon in which a film on the surface of a substrate ruptures and forms droplets. Several approaches such as substrate modification and capping layers have been shown to improve film strength and prevent rupturing. However, these methods often cause substantial changes in the functional properties of the thin film.

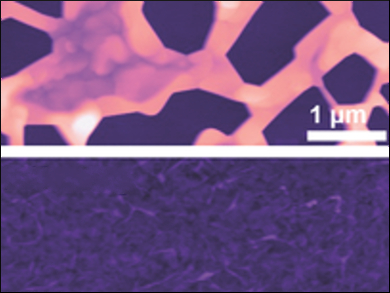

Ke Xu, Michael F. Crommie, Ting Xu, University of California, Berkeley, USA, and colleagues have developed 2D capping layers from graphene and MoS2 monolayers that suppress the dewetting of thin films without significantly altering their physical properties. The monolayers were prepared through chemical vapor deposition (CVD) of graphene and MoS2 and subsequently transferred onto thin films of polymers, organic semiconductor small molecules, or polycrystalline metal. Upon annealing, no dewetting was observed for graphene and MoS2 capped films (pictured bottom). In comparison, uncapped films readily dewetted under the same conditions (pictured top).

The researchers demonstrated that the control of dewetting with 2D capping layers made of graphene and MoS2 results from the exceptionally high Young’s moduli, the solids stiffnesses, of the materials. Indeed, thermodynamic modeling showed that the capping layers lessened the deformation of the thin films under stress and thus prevented dewetting.

- Preventing Thin Film Dewetting via Graphene Capping,

Peigen Cao, Peter Bai, Arash A. Omrani, Yihan Xiao, Kacey L. Meaker, Hsin-Zon Tsai, Aiming Yan, Han Sae Jung, Ramin Khajeh, Griffin F. Rodgers, Youngkyou Kim, Andrew S. Aikawa, Mattew A. Kolaczkowski, Yi Liu, Alex Zettl, Ke Xu, Michael F. Crommie, Ting Xu,

Adv. Mater. 2017.

DOI: 10.1002/adma.201701536