Burning coal produces SO2 due to sulfur impurities. This gas can be harmful to the environment and human health. Thus, it needs to be removed from flue gas. It can, for example, be adsorbed by porous materials such as zeolites. However, the available materials often have low adsorption capacities or slowly degrade upon contact with SO2.

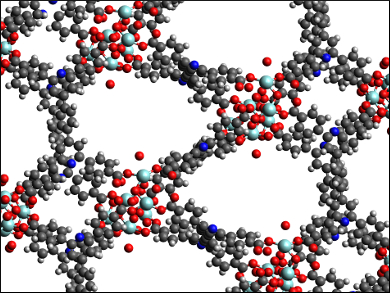

Sihai Yang, Martin Schröder, University of Manchester, UK, and colleagues have developed a zirconium-based metal–organic framework (MOF) for SO2 absorption. The team used 4,4′,4”,4”’-(1,4-phenylenebis(pyridine-4,2,6-triyl))tetra benzoic acid (H4L) as the organic component and mixed it with ZrCl4 and benzoic acid in dimethylformamide (DMF) at 120 °C. The resulting porous material was treated with an HCl solution to give the desired MOF, [Zr6(μ3-O)4(μ3-OH)4(OH)4(H2O)4L2], named MFM-601 (structure pictured).

The synthesized framework has a high specific surface area of 3644 m2 g–1. The material is robust and has the highest SO2 adsorption capacity observed in porous solids with 12.3 mmol g−1 at 298 K and 1 bar. The binding of SO2 is selective over CO2 and N2. The MOF’s structure and the SO2 binding mode were determined using high-resolution synchrotron powder X-ray diffraction. According to the researchers, the adsorption performance can be explained by the efficient packing of SO2 in the pores, with similar intermolecular distances to those in solid SO2. This allows favorable SO2−SO2 dipole interactions.

- Exceptional Adsorption and Binding of Sulfur Dioxide in a Robust Zirconium-Based Metal–Organic Framework,

Joseph H. Carter, Xue Han, Florian Y. Moreau, Ivan da Silva, Adam Nevin, Harry G. W. Godfrey, Chiu C. Tang, Sihai Yang, Martin Schröder,

J. Am. Chem. Soc. 2018.

https://doi.org/10.1021/jacs.8b08433