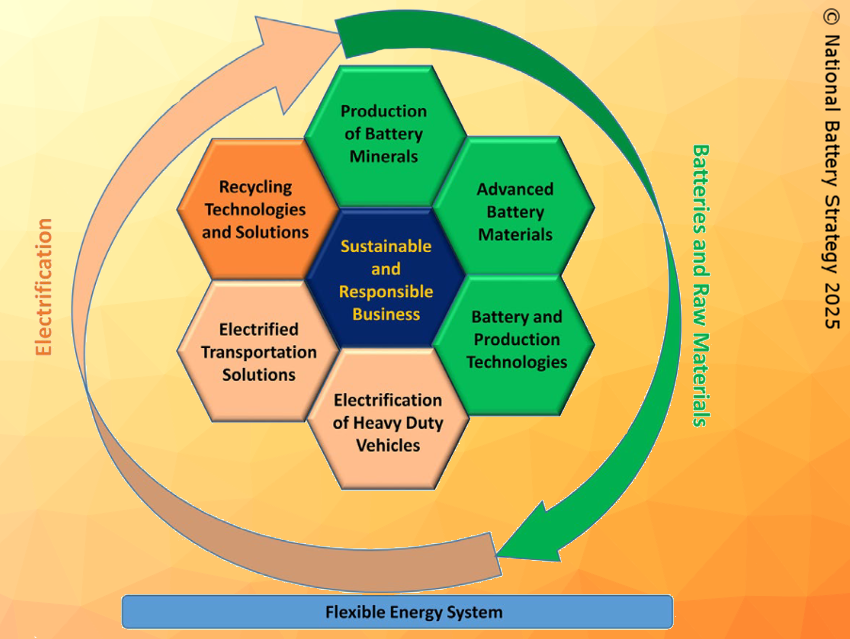

Finland has set a target to become carbon neutral by 2035. As part of this process, in January 2021 it became one of the first countries in the world to publish a national battery strategy. The electrification of society, transport, and heavy-duty machines is a massive challenge. The batteries making the “digi green” transformation possible must be produced in a sustainable and responsible way and it is vital to make sure that batteries are part of the solution, not part of the problem Finland aims to strengthen its role as a pioneer in sustainable battery manufacturing and recycling and to become a major international player in the battery and electrification sector.

Finland is one of the few European countries that has all the key minerals needed to make lithium-ion batteries: cobalt, nickel, lithium, and graphite. The European Commission aims to reduce dependence on the imports of battery raw materials. In addition, Finland has expertise throughout the entire battery value chain, from mining and processing of raw materials to technologies and services related to battery manufacture and use, as well as charging technologies and recycling.

One of the key elements of a sustainable and competitive battery ecosystem is recycling. Finland has been chosen to coordinate the European battery industry’s research on this topic. Other cornerstones of the strategy include responsible production and processing of minerals, improved traceability and recyclability of raw materials, and new technological solutions. The country is keen to engage in dialogue with other countries on halving transport emissions by 2030 and developing a sustainable battery industry.

The authors of the Finnish Battery Strategy say there is no time to lose if Europe wants to succeed in the global battery race. They see the emerging new battery industry as one of the biggest opportunities Finland has faced in recent years.

BASF, Ludwigshafen, Germany, is building its first European battery materials production plant in Harjavalta, Finland. With this plant for active cathode precursor materials, BASF contributes to the development of a sustainable battery ecosystem by reducing energy consumption in the production phase, using renewable energy sources and low CO2 raw materials, and significantly shortening supply chains.

Fortum Oyj, Espoo, Finland, has developed a low-CO2 recycling process that makes over 80 % of the battery recyclable and uses the materials to make new batteries. Nickel, cobalt, lithium, and other scarce metals can be reused.

Electrification of mining equipment enables the elimination of underground exhaust emissions and improves the sustainability of a mining operation while reducing ventilation and fuel costs. Sandvik, Stockholm, Sweden, plans to introduce a new suite of electrical equipment by the end of 2021, including a complete range of battery-powered drilling rigs for all underground drilling applications.

- From battery minerals to battery recycling—Finland leads the way towards a sustainable future through batteries and electrification, Business Finland May 12, 2021.

- Battery Strategy 2025, Ministry of Economic Affairs and Employment of Finland 2021. ISBN pdf: 978-952-327-725-0

- New Battery Materials Production Site in Europe, ChemistryViews February 12, 2020.