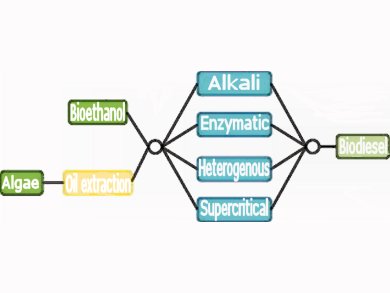

So far there are few processes reported for the production of biodiesel using ethanol, and most of the studies are at laboratory scale evaluating the operating conditions of the reactor. Ignacio E. Grossmann and colleagues, Carnegie Mellon University, Pittsburgh, PA, USA, optimized the production of biodiesel from algae using bioethanol following four different transesterification paths: alkali, enzymatic, and heterogeneous catalysts and noncatalyzed under supercritical conditions.

The most promising raw material for oil is microalgae, due to the high yield from the field to oil, and the higher purity compared to the use of wastes.

The reseachers solved a superstructure of the alternative technologies by decomposing it for each of the technologies. They are simultaneously optimized and heat integrated according to a specified objective function. The optimal heat exchanger and water networks and an economic evaluation are determined after this optimization.

Simultaneous optimization and heat integration of the flowsheets result in optimal operating conditions in the reactors that differ significantly from the ones traditionally used because the separation stages were not taken into account when deciding on the reactor design.

For the production of biodiesel using bioethanol two interesting technologies, alkali and enzyme catalyzed, were identified. The alkali catalyzed one is currently the cheapest and is even competitive with the use of methanol as a transesterfying agent, but the energy and water consumptions are higher than in the case of using an enzymatic catalyst. The main drawback of the enzymatic process currently is the cost of the enzyme.

Even though the current prices of ethanol and methanol support the use of the enzymatic process for the production of biodiesel, the promising production costs and the advantages of integrated production of ethanol and biodiesel, make the transesterification of oil with ethanol a promising alternative in the context of a biorefinery complex.

Further validation of these results is needed at pilot plant scale due to the conceptual nature of our work.

- Optimal integration for biodiesel production using bioethanol,

Kristen Severson, Mariano Martín, Ignacio E. Grossmann

AIChE J. 2012.

DOI: 10.1002/aic.13865