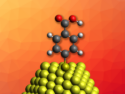

Semiconductors are vital components in solar cells, LEDs, and many other electronics. Koji Usami and colleagues, Niels Bohr Institute, University of Copenhagen, Denmark, have produced a semiconductor membrane with a thickness of 160 nm and an unprecedented surface area of 1 by 1 mm to demonstrate efficient cooling of semiconductors.

When laser light hits the semiconductor membrane, some of the light is reflected and the light is reflected back again via a mirror in the experiment so that the light flies back and forth in this space and forms an optical resonator. Some of the light is absorbed by the membrane and releases free electrons. The electrons decay and thereby heat the membrane. This gives a thermal expansion. In this way the distance between the membrane and the mirror is constantly changed in the form of a fluctuation.

Changing the distance between the membrane and the mirror leads to a complex and fascinating interplay between the movement of the membrane, the properties of the semiconductor and the optical resonances. It is possible to control the system so as to cool the temperature of the membrane fluctuations. This is a new optomechanical mechanism. Even though the membrane as a whole is getting a little bit warmer, the membrane is cooled at a certain oscillation and the cooling can be controlled with laser light. The membrane fluctuations were cooled to –269 °C.

The potential of optomechanics could, for example, pave the way for cooling components in quantum computers. Efficient cooling of mechanical fluctuations of semiconducting nanomembranes by means of light could also lead to the development of new sensors for electric current and mechanical forces. Such cooling in some cases could replace expensive cryogenic cooling, which is used today, and could result in extremely sensitive sensors that are only limited by quantum fluctuations.

- Optical cavity cooling of mechanical modes of a semiconductor nanomembrane,

K. Usami, A. Naesby, T. Bagci, B. Melholt Nielsen, J. Liu, S. Stobbe, P. Lodahl, E. S. Polzik,

Nature Physics 2012.

DOI:10.1038/nphys2196