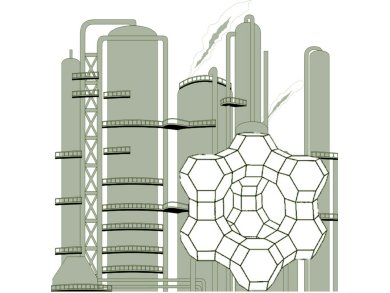

Hierarchical zeolites are an emerging new area in the mature field of zeolites. Their bimodal pore structure, i.e., zeolitic micropores and intracrystalline mesoporosity, makes them ideal to process large molecules which are too big to enter into the pores of conventional zeolites.

Mesostructured zeolites [1] are a new class of zeolites with intracrystalline mesoporosity. The pore size of mesostructured zeolites can be precisely controlled by the use of surfactants of different sizes. At the same time all the desired properties of conventional zeolites such as strong acidity and excellent hydrothermal stability remain.

Javier Garcia-Martinez, Rive Technology, Inc., New Jersey, USA, and University of Alicante, Spain, and colleagues, report on the first successful manufacturing on a commercial scale of mesostructured zeolite Y by a unique post-synthetic surfactant –templated process. Approximately 30 t were manufactured in a commercial zeolite manufacturing plant utilizing existing equipment. In a 70 day commercial refinery trial, fluid catalytic cracking (FCC) catalysts, made from the mesostructured Y zeolites, demonstrated excellent hydrothermal stability under commercial operating conditions and good activity. They showed higher selectivity and reduced the production of heavy bottoms and coke compared to conventional methods. The economic benefits are estimated at $0.91/bbl at full catalyst change-out.

- Mesostructured Y Zeolite as Superior FCC Catalyst – From lab to Refinery,

Javier Garcia-Martinez, Kunhao Li, Gautham Krishnaiah,

ChemComm 2012.

DOI: 10.1039/C2CC35659G

[1] Mesostructured zeolite Y – high hydrothermal stability and superior FCC catalytic performance,

Javier García-Martínez, Marvin Johnson, Julia Valla, Kunhao Li, Jackie Y. Ying,

Catal. Sci. Technol. 2012, 2, 987-994.

DOI: 10.1039/C2CY00309K

i want to the papers on molemaler highway of zeolite