10 to 80 % of the hydraulic fracturing fluid returns to the surface as wastewater. It is comprised of large volumes of water containing chemical additives and proppant, typically silica, and is also enriched with materials from the shale formation, such as brines, hydrocarbons, and naturally occurring radioactive materials. Currently, this wastewater is reused, injected into deep storage wells, or send through sewage treatment plants. In response to public concern over elevated bromide levels in the Pennsylvania Monongahela River watershed, the Pennsylvania Department of Environmental Protection (PADEP) asked in May 2011 that the state’s treatment plants voluntarily stop processing fracking wastewater.

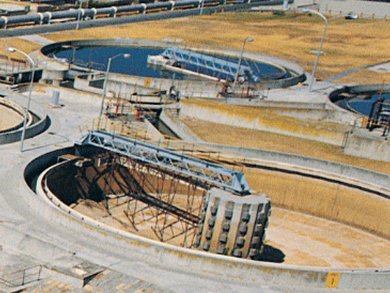

Kyle J. Ferrar and colleagues, University of Pittsburgh, PA, USA, for the first time characterized effluents from wastewater treatment plants (WWTPs) containing such unconventional natural gas development (UNGD) wastewaters with a variety of spectroscopic techniques. The effluent samples were collected while wastewater was being treated and discharged from the outfalls of three WWTPs – two municipal, publicly owned and a commercially operated industrial wastewater treatment plant.

Certain analytes including barium, strontium, bromides, chlorides, total dissolved solids, and benzene were measured in the effluent at concentrations above water quality criteria. It is likely that the elevated analyte concentrations were due to the presence of UNGD wastewater in the WWTP effluent as analyte concentrations decreased once acceptance of UNGD wastewaters ceased or was reduced.

The researchers see this as preliminary evidence that these and similar WWTPs may not be able to provide sufficient treatment for UNGD wastewater. Due to temporal variability measured in the effluents, they recommend constant monitoring of a comprehensive suite of analytes at WWTPs that continue to accept UNGD wastewater.

- Assessment of Effluent Contaminants from Three Facilities Discharging Marcellus Shale Wastewater to Surface Waters in Pennsylvania,

Kyle J. Ferrar, Drew R. Michanowicz, Charles L. Christen, Ned Mulcahy, Samantha L. Malone, Ravi K. Sharma,

Environ. Sci. Technol. 2013.

DOI: 10.1021/es301411q

Also of interest:

- What is Shale Gas? How Does Fracking Work?

ChemistryViews.org 2013