Removing most types of organic pollutants from wastewater is a challenge. Samuel Sánchez and colleagues, Max Planck Institute for Intelligent Systems, Stuttgart, Germany, have created a two-layered, self-propelled microscopic cleaning system. Their microjets are based in the Fenton reaction, one of the most popular advanced oxidation processes for the degradation of organic pollutants. A combination of iron and hydrogen peroxide is used to oxidize organic pollutants, thereby degrading them to carbon dioxide and water. The multi-stage reaction is catalyzed by Fe(II) ions.

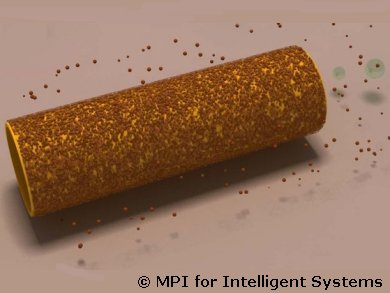

A 100–200 nm thin layer of iron was evaporated onto a glass surface coated with a dense pattern of aligned lacquer squares. In a second step, a platinum layer of 1 nm thickness was added, using a special sputtering technique. Due to the different mechanical properties of the metals, the double layer starts to roll up into a tube-shape once the lacquer layer is removed.

The inner platinum layer acts as a catalyst for the decomposition of hydrogen peroxide into water and oxygen. Differing amounts of oxygen exit on either side of the tube and the tube is randomly jet-propelled. As soon as the tube has reached a certain speed, all bubbles escape to one side, and the tube is thrust into the opposite direction of the escaping bubbles, thereby feeding more fuel into the front end.

At the outer cleaning layer hydrogen peroxide reacts with organic pollutants in the presence of iron. The Fe(II) ions are formed when the iron on the outer tube surface establishes contact with water.

Because the iron layer is magnetic, the tubes can be steered to pollutants that are difficult to reach and they can be recovered afterwards.

According to the scientists the oxidation of organic pollutants achieved by a swarm of their self-propelled microjets is twelve times higher than when using immobile iron microtubes.

- Max-Planck-Gesellschaft, Munich, Germany