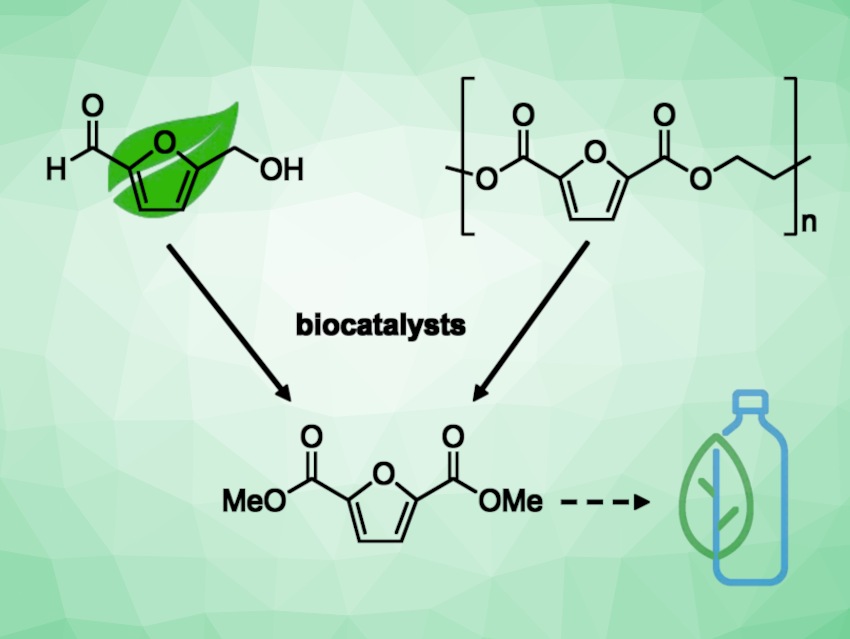

Petrochemically-derived plastics have become essential to our way of life. Bioplastics that can be produced sustainably from renewable resources could help to alleviate the harmful environmental effects of plastics use. Bioderived furan derivatives such as 2,5-furandicarboxylic acid (FDCA) can be used as precursors to bioplastics. Prior to polymerization, FDCA is activated as its dimethyl ester (pictured above in the bottom row). However, this can be energy-intensive and/or require the use of toxic reagents.

Andrew J. Carnell, University of Liverpool, UK, and colleagues have engineered a carboxyl methyltransferase enzyme that can catalyze the dimethylation of FDCA. The carboxyl methyltransferase FtpM, first identified in Aspergillus fumigatus, can methylate a range of mono- and dicarboxylic acids. When using this enzyme, the first methylation of FDCA is much faster than the second methylation. This leads to a need for a high enzyme loading when FtpM is used to convert FDCA to its dimethyl ester.

The team created an AlphaFold 2 model (i.e., a prediction of protein structure) of the enzyme and noted that the active site contained a large number of arginine residues, which make the active site internal surface highly electropositive. This is thought to be unfavorable for binding the initially formed monomethyl ester. Using rational mutagenesis, the group improved the activity of the FtpM enzyme for the second methylation step without significantly adversely affecting the first methylation. This resulted in the mutant R166M, which can catalyze full conversion of FDCA to its dimethyl ester FDME.

The group used the mutant in two multienzyme cascades that show efficient conversion of either cellulose-derived hydroxymethylfurfural (HMF, pictured at the top left) or milled poly(ethylene furanoate) (PEF) plastic (pictured at the top right) to FDCA and then to the bioplastic precursor FDME. This demonstrates the potential of the approach for the recycling of waste plastic.

- Engineering a Carboxyl Methyltransferase for the Formation of a Furan‐Based Bioplastic Precursor,

Lucy C. Ward, Ellie Goulding, Daniel J. Rigden, Faye E. Allan, Alessandro Pellis, Harry Hatton, Georg M. Guebitz, J. Enrique Salcedo-Sora, Andrew J Carnell,

ChemSusChem 2023.

https://doi.org/10.1002/cssc.202300516