Lithium-ion batteries (LIBs) provide portable devices like tablets and mobile phones—and increasingly also vehicles—with power. As the share of volatile renewable energy needing electricity storage increases, more and more LIBs are needed, lithium prices rise, resources dwindle, and the amount of depleted batteries that contain toxic substances increases. Qinghai Meng, Yu-Guo Guo, Beijing National Laboratory for Molecular Sciences, Chinese Academy of Sciences, and colleagues have developed a new approach for the recovery of lithium from used LIBs.

Lithium Extraction from Electrodes

The recycling of LIBs is a difficult undertaking. The recovery of lithium of a quality high enough to be used again is complicated and expensive. Most recycling processes are targeted at extracting the lithium from cathodes (where most of the lithium in discharged batteries is located). However, it then precipitates out together with other metals contained in the cathode and must be painstakingly separated.

Extraction from the anodes, which consist primarily of graphite, is significantly more efficient and can be carried out without discharging the battery beforehand. Because of their high reactivity, however, the risk of fires and explosions is high if the anodes are leached out with aqueous solutions, as is usual. These reactions release large amounts of energy and may produce hydrogen.

Polycyclic Aromatic Hydrocarbons for Lithium Capture

The team has developed an alternative method that avoids these problems. Instead of water, they use aprotic organic solutions to recover lithium from anodes. Aprotic substances cannot release any hydrogen ions, so no hydrogen gas can form.

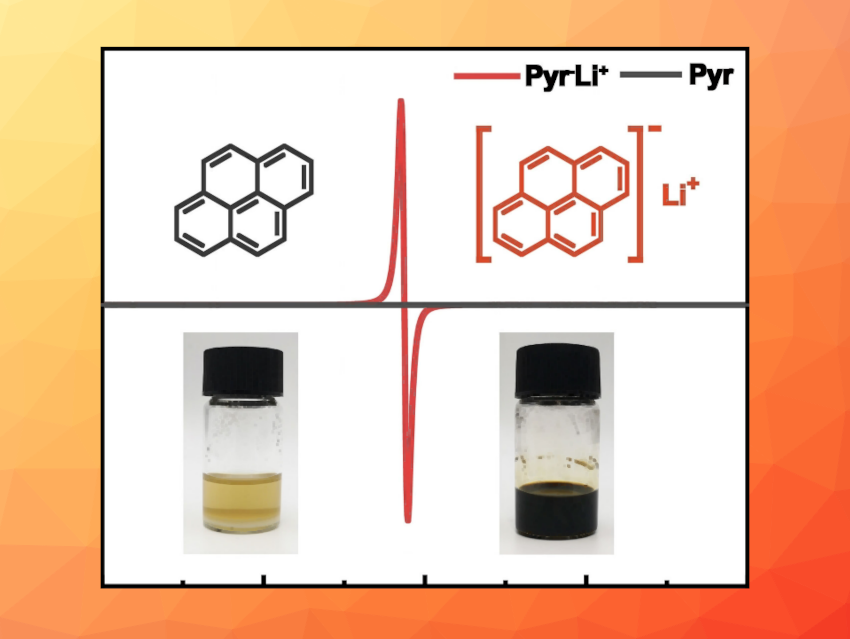

The solutions consist of a polycyclic aromatic hydrocarbon (PAH) and an ether as the solvent. Certain PAHs can take up a positively charged lithium ion from the graphite anode together with one electron. Under mild conditions, this redox reaction is controlled and very efficient. The team used the structural diversity of PAHs and screened several candidates with suitable potential. They found that with pyrene as the PAH in tetraethylene glycol dimethyl ether, it was possible to dissolve the active lithium from the anodes almost completely.

Direct Reuse as a Lithiation Reagent

An additional advantage of the approach is that the resulting lithium-PAH solutions can be used directly as reagents, for example, in adding lithium to new anodes in preprocessing or in regenerating spent cathodes. The PAH/solvent system can be varied to optimize it for the material being treated.

This recovery process is efficient and inexpensive, reduces safety risks, avoids waste, and opens new prospects for the sustainable recycling of lithium-ion batteries.

- Potential Controllable Redox Couple for Mild and Efficient Lithium Recovery from Spent Batteries,

Xin Chang, Min Fan, Boheng Yuan, Chao‐Fan Gu, Wei‐Huan He, Chen Li, Xi‐Xi Feng, Sen Xin, Qinghai Meng, Li‐Jun Wan, Yu‐Guo Guo,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202310435