A project consortium consisting of four partners from industry and research: Evonik (Robert Franke, Head of Hydroformylation Research coordinates the project), the Leibniz Institute for Catalysis (LIKAT), the Leibniz Institute for Plasma Research (INP), and Rafflenbeul Anlagenbau GmbH has launched the PlasCO2 project to use CO2 as a raw material in the production of C4 chemicals. The German Federal Ministry of Education and Research (BMBF) is funding the project with more than €1.8 million (funding code b 33RC030).

PlasCO2 stands for ‘Plasma-induced generation of carbon monoxide from carbon dioxide and its chemical utilization’. The researchers are working on extracting synthesis gas from CO2 and H2 by using a plasma reactor. In industry, synthesis gas is an important starting material for the synthesis of higher-value hydrocarbons.

Plasmas are formed when gases are exposed to strong electric fields. The electric voltage tears electrons from the gas molecules, which collide with other molecules. This forms a reactive mixture of free electrons, ions, and molecular fragments that come together to create new molecules.

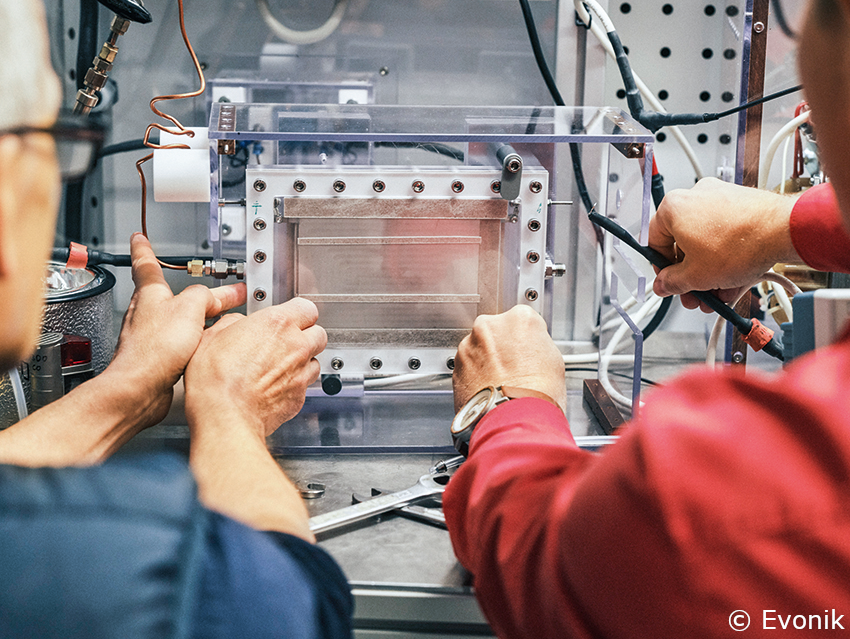

Plasma reactors are considered an alternative for making CO2 reactive. The team is currently testing several ways to turn CO2 into valuable products by using a small, low-temperature laboratory reactor that operates at 40 watts (pictured). The idea is to use CO2 from industrial waste gases and produce H2 with the help of renewably generated electricity that splits water in electrolysis plants, and to combine the plasma reactor with follow up chemistry (hydroformylation), in sequence and in one reactor.

INP is responsible for the development of the plasma technology and the drafts for the reactor design, which will then be implemented in concrete plants by Rafflenbeul. The initial links between the plasma reactor and the chemical reactors are carried out at LICAT, as is the optimization of the catalysts. Evonik is primarily taking care of the quantum chemical calculations and will carry out the ecological and economic evaluation on the basis of life cycle analyses.

A pilot plant that creates the plasma with renewable resources is expected to be built in about four years. The vision is that small, easily scalable, and variably deployable reactors will enable a wide range of applications in the chemical industry wherever synthesis gas is to be used.

- Evonik Industries AG, Marl, Germany

- Leibniz Institute for Catalysis (LIKAT), Rostock, Germany

- Leibniz Institute for Plasma Research (INP), Greifswald, Germany

- Rafflenbeul Anlagenbau GmbH, Langen, Germany

- Elements Magazine, Evonik 2023. (accessed January 24, 2023)