RISE and Apple have developed a bio-based cellulose foam from responsibly sourced wood pulp to replace fossil-based polymer foams in packaging, insulation, and lightweight composites. This foam is recyclable in the paper packaging stream and is easy to manufacture. It has good compressive resistance.

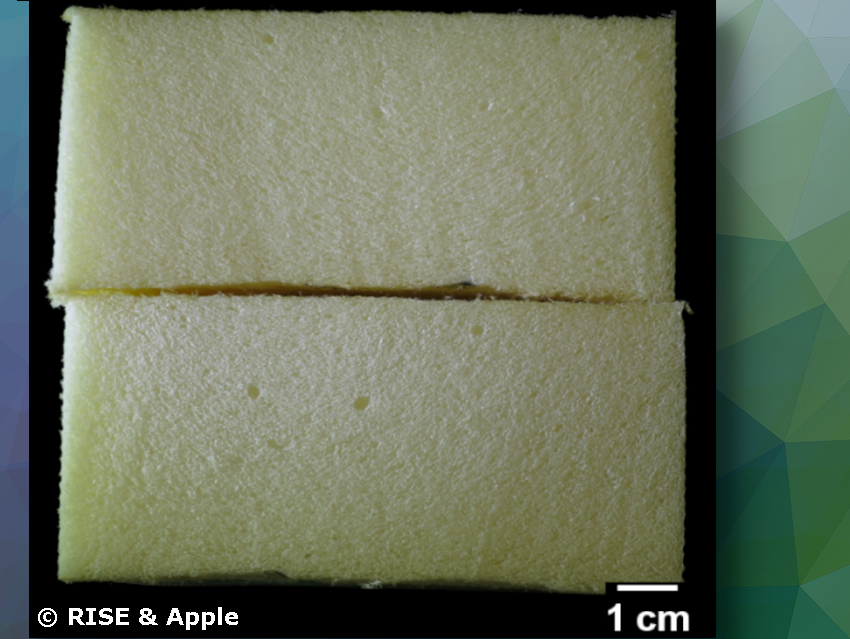

The low density foam has a high pulp content and a foam-like load deformation behavior with a stiff initial response followed by greater compliance. It has a uniform structure characterized by sub-millimeter pores. At first glance, the material bears a strong resemblance to some conventional polymer foams. However, at the microscopic level, the structure is quite different, as the material is composed of a network of fibers rather than polymer molecules.

The primary interest of RISE and Apple is to ensure the commercial availability of low-density, pulp-based materials in large quantities. They say they are looking for partners to further develop and apply the material. They envision collaborations that either align with their material goals or explore new directions, leading to shared benefits such as better manufacturing technology.

- Research Institutes of Sweden AB (RISE), Gothenburg, Sweden

- Apple, Cupertino, CA, USA

- Behna Mueller, Klas Johansson, Prashanth Srinivasa, Göksü Cinar Cikci, Dina Dedic, Wayne Cowan, John Glass, Mike Long, Connie Yang, Cellulose Foams: Sustainable Solutions to Replace Fossil-Based Plastic Foams, White Paper April 2024.